Coating Systems

Automatic and double sided screen coating solutions ideal for large industrial and textile screen printers

Key features of the Coating Systems

- Fully automatic operation

- Fully adjustable

- Pressure regulating function

- Operating system in multiple languages

- Special corrosion-resistant treatment aluminium scoop coater

Adelco’s coating equipment is suitable for printing screens with high precision, using photographic emulsion coating.

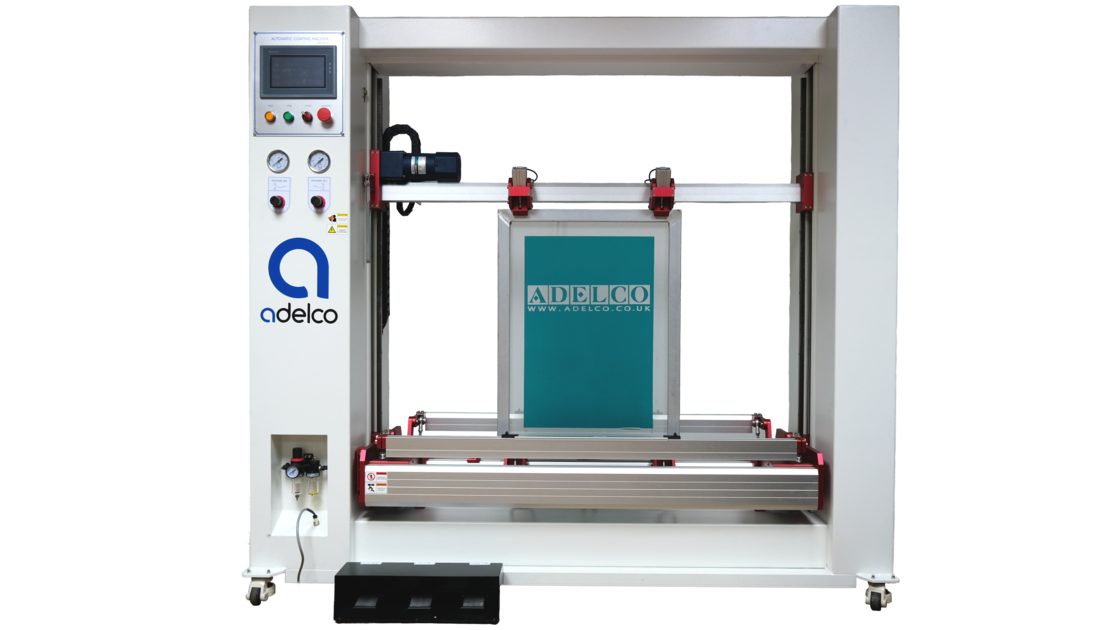

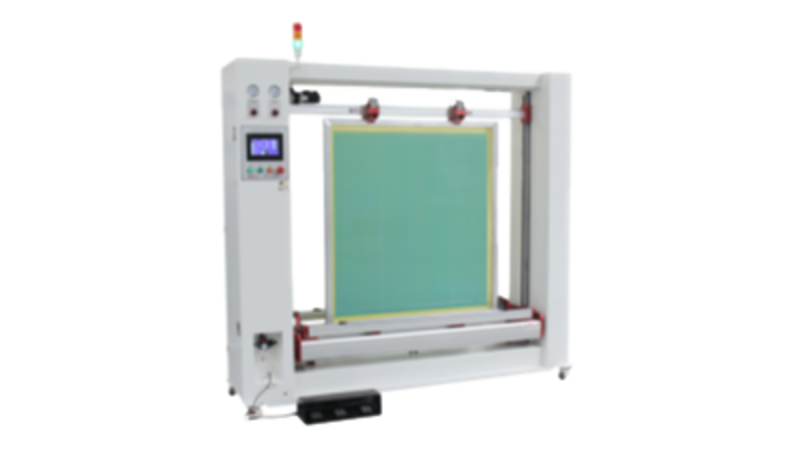

Adelco HC-1010AD & HC-1313AD

- PLC programmable controller and HMI composition as the operating control system.

- With full automatic operation via touch-screen settings, ordinary plate-maker can be used to produce high-quality precision screens with ease.

- Fixing clamps / Unlock clamps set by a foot switch which controls the air pressure, easy to load and unload screens.

- Coating speed, coating time and a single, double-sided coating can be freely set.

- With pressure regulating function, the coating thickness can be controlled via a set number of application times and by applying pressure.

- When reaching the stop position, the machine would automatically slow down to 20mm near the frame, no need to fix the screen with extra edges.

- The use of rail steel with special low vibration creates a ripple-free coating process.

- The operating system comes with multi-languages, multiple coating patterns, and detailed parameter settings.

- Special corrosion-resistant treatment aluminium scoop coater, with no clearance with the coating structure, maintains a stable emulsion coating.

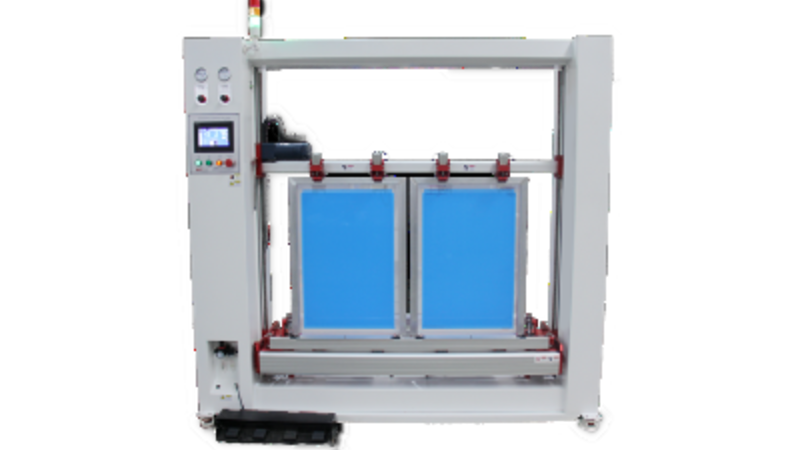

Adelco HC-6510ADD

- Servo motor + PLC programmable controller and HMI composition as the operating control system.

- Fully automatic operation via touch-screen settings, an ordinary plate-maker can easily produce high-quality precision screens.

- Fixing clamps / Unlock clamps can be set by a foot switch that controls the air pressure, allowing for easy loading and unloading of screens.

- The coating speed, coating time and a single, double-sided coating can be freely set.

- With the pressure regulating function, the coating thickness can be controlled via a set number of application times and applying pressure.

- When reaching the stop position, the machine will automatically slow down to 20mm near the frame, no need to fix the screen with extra edges.

- The use of rail steel with special low vibration allows for a ripple-free coating process.

- The operating system comes with multiple languages (Chinese/English/Korea), multiple coating patterns, and detailed parameter settings.

- Special corrosion-resistant treatment aluminium scoop coater, with no clearance with the coating structure, maintains a stable emulsion coating.

- The Servo motor keeps coating accuracy to ±1um.

- Two screens being coated at one time is optional.

| Model | Adelco HC-1010AD | Adelco HC-1313AD | Adelco HC-6510ADD |

|---|---|---|---|

| Max frame size (mm) | 1000 x 1000 | 1300 x 1300 | Two 508 x 609.6, 584.2 x 787.4, 635 x 914.4 |

| Min frame size (mm) | 400 x 400 | 400 x 400 | 400 x 400 |

| Max coating area (mm) | 880 x 880 | 1180 x 1180 | Two 650 x 1000 |

| Min coating area (mm) | 200 x 200 | 200 x 200 | 200 x 200 |

| Longest coater length | 880 mm | 1180 mm | 650 mm |

| Shortest coater length | 200 mm | 200 mm | 200 mm |

| Coating thickness | 15 - 35 mm | 15 - 35 mm | 15 - 35 mm |

| Coating precision | +0.001 mm | ±0.001 mm | ±0.001 mm |

| Coating time | Front and back side 0 - 999 times | Front and back side 0 - 999 times | Front and back side 0 - 999 times |

| Coating time setting | Four process time free set | Four process time free set | Four process time free set |

| Coating pressure | 2 - 6 kg / cm2 adjustable | 2 - 6 kg / cm2 adjustable | 2 - 6 kg / cm2 adjustable |

| Coating speed | 5 - 150 mm/sec | 5 - 150 mm/sec | 5 - 150 mm/sec |

| Operating system | HMI +PLC | HMI +PLC | HMI +PLC |

| Frame Fixing | Foot switch quick fixed | Foot switch quick fixed | Foot switch quick fixed |

| Air Pressure | 6 kg/cm2 | 6 kg/cm2 | 6 kg/cm2 |

| Equipment weight | 400 KG | 600 KG | 500 KG |

| Power | 220V x 1ph x 1KW 415V * 3PH | 220V x 1ph x 1KW | 220V x 1ph x 1KW |

| Dimensions | W: 1876 x D: 614 x H: 1780 mm | W:2076 x D:614 x H:2056 mm | W:2076 x D: 614 x H: 2056 mm |

| Packing Size (L x W x H) | 1950 x 690 x 1980mm | 2260 x 850 x 2200mm | 2260 x 850 x 2200mm |

Make an enquiry now

Register your interest in the Coating Systems now. We guarantee you won't be disappointed.