FAQ

We've collected some of our most frequently asked questions here and answered them for your convenience.

General FAQ

- Who are Adelco?

-

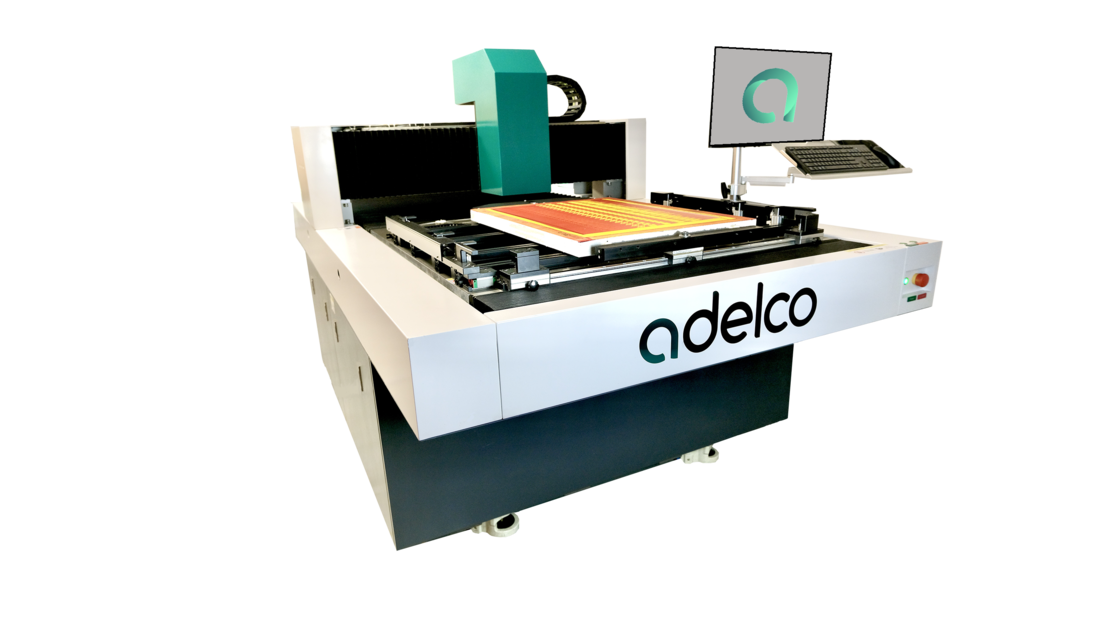

Adelco is a manufacturer of textile dryers and printers. Our products are known for reliability, longevity and innovation.

Adelco has a manufacturing facility in China, a UK-based sales and service support centre, and a worldwide distributor network.

Digital Printing (DTG) FAQ

- What does DTG stand for?

-

DTG stands for Direct To Garment, this is the process of printing digital images onto garments and textiles using inkjet technology. The results are accurate and able to print many different designs fast and with ease.

Check out our blog for more details: https://www.adelco.co.uk/news/can-dtg-grow-and-boost-your-screen-printing-business or visit our DTG Printing Machine range.

- What are the benefits of digital printing?

-

Digital textile printing benefits from a higher resolution and photographic quality than screen printing.

Digital printing machines offer quicker set-up and print times, require minimal cleaning, and with ink costs coming down are the most cost-effective printing method for small volume production thanks to their low production costs and process.

Other benefits include:

- Reduced colour matching time.

- Digital printing is a simple process, requiring little experience or knowhow.

- Able to automate the work process from an on-line order to the packing room.

- Environmentally friendly, water based inks, reduced cleaning times and chemicals.

- What are the advantages and disadvantages of digital printing?

-

Advantages:

- Digital printing is quick and easy to set up.

- Low costs for small runs.

- Large colour gamut

- Small footprint.

- Cleaner and more environmentally friendly.

Disadvantages:

- High cost at large volume compared to screen printing.

- Software updates.

- If not maintained correctly will require expensive repairs.

- What is the difference between screen printing and digital printing?

-

Screen printing is a more traditional method used to print customised designs on textiles and fabrics. It involves putting a design onto a screen and turning it into a stencil with the use of UV light. It then pushes layers of ink through the screen into the fabric beneath, one colour at a time. Screen printing is more cost-effective for printing high-volume custom orders.

Digital printing, also known as DTG (direct to garment), uses a digital textile printer attached to a computer that sends the artwork via print heads (much like a paper printer) to the fabric. Digital prints do need a base of pre-treatment before the printing process can begin, as this enables the ink to bond to the fabric.

Both methods require curing through a hot air dryer for the print to bond and be washed fast on the fabric.

Check out this blog for more details: https://www.adelco.co.uk/news/can-dtg-grow-and-boost-your-screen-printing-business

- Is digital printing more expensive than screen printing?

-

There are two main factors to answer this question:

- Run length

- Number of colours for the print

Each digital printer carries different setup costs. The ink cost is more expensive in digital printing compared to screen printing machines.

However, there is a window where digital print is cheaper than screen. Screen print lends itself to much higher run lengths. Digital lends itself to more one offs and smaller run lengths.

E.g. It would be cheaper to digitally print a 20 shirt run with 10 colours, than make up 10 individual screens.

Rule of thumb: For runs under 500 pieces, digital printing machines are the more economic option, as there are fewer setup costs and the time to print them is much quicker. For runs over 500 pieces, screen printing machines is worth the set up time and costs.

Check out this blog for more details: https://www.adelco.co.uk/news/can-dtg-grow-and-boost-your-screen-printing-business

- Which method is best for t shirt printing?

-

There are a few methods for printing on t shirts and the simple answer to this question is that it depends on the volume of the production run and the type of finish you are looking to achieve.

Generally speaking, digital printing is an economic option for production runs under 500 units, and the set-up time and costs for screen-printing are more worthwhile for runs in excess of 500 units.

The most common methods for textile printing are screen-printing, DTG (direct to garment), heat transfer and sublimation. They all have pros and cons.

- How long does digital printing last?

-

Depending on the type of digital printing machine used, these do vary in quality and provided care is taken when washing, the print will last as long as the garment. Both the print and t-shirt will fade from approx. 50 washes.

- What is the best DTG printer?

-

The best digital printer will depend on your budget and production capability requirements. There is plenty of choices when looking to purchase a DTG printer, with the option of used or new equipment.

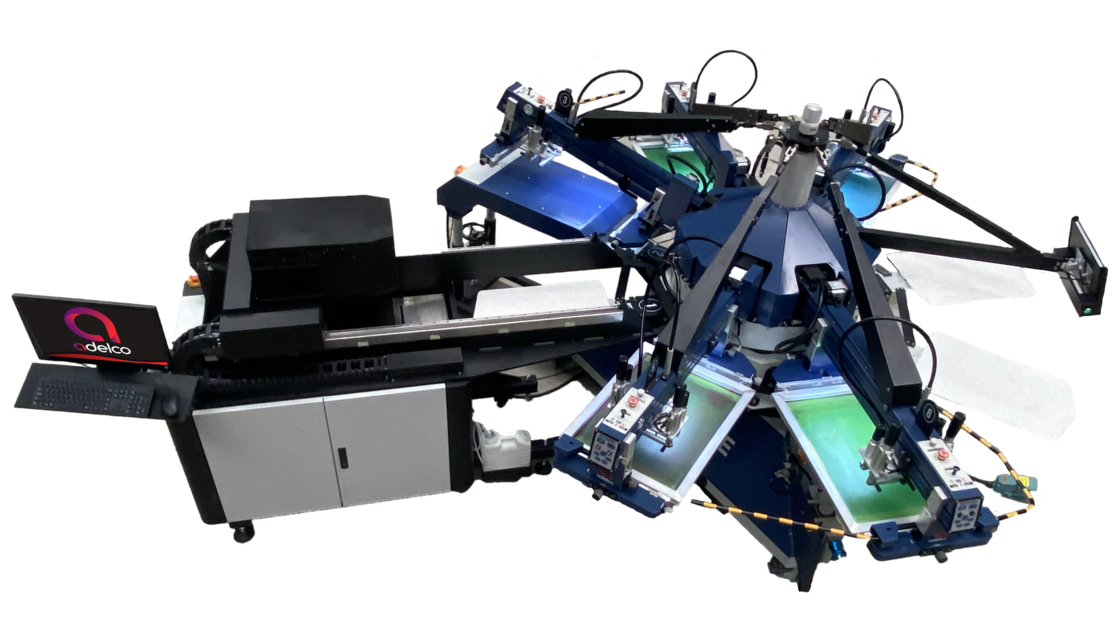

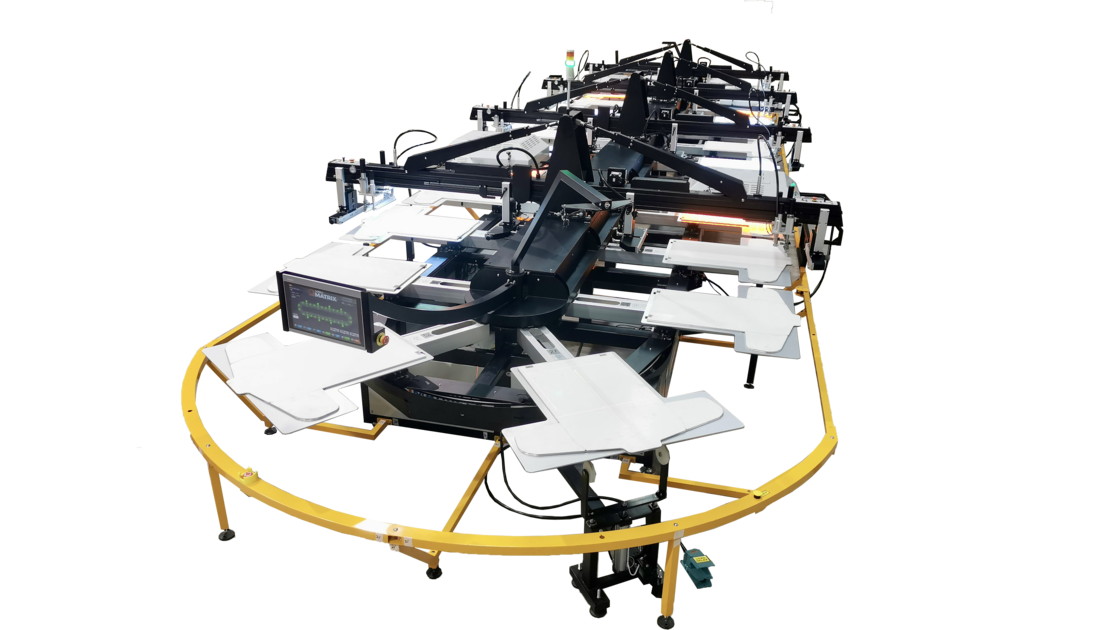

The fastest DTG printer is the OvalJet which produces up to 240 prints per hour, with one operator. It produces the best quality prints, at the lowest print cost.

- Which fabric is best for digital printing?

-

The best fabric for digital printing would be 100% cotton as this lends itself to the process, but other fabrics work well. Much depends on the model of the printer as these do vary in what they can offer and produce.

The more budget-friendly printing machines can print well on cotton, cotton blends, linen, viscose and leather. Whereas high-spec printers are able to print on almost any type of fabric including silk, polyester, wool, denim and lycra to name a few.

- Can DTG print on polyester?

-

Printing with Direct to garment printers onto polyester can be problematic, largely due to Dye migration.

Using more pre-treatment before printing and slowing down the print settings combined with a longer curing time at a lower temperature, can improve prints on polyester.

- Which is better digital or screen printing?

-

They both have advantages and disadvantages, Digital is quicker, cleaner, and more cost-effective for e-commerce and fulfilment, and screen printing is more economical for printing the same design many times. To answer this fully, check out this blog for more details: https://www.adelco.co.uk/news/can-dtg-grow-and-boost-your-screen-printing-business

Screen Printing FAQ

- What materials do I need for screen printing?

-

If you’re wanting to set-up a screen printing business, there’s a few things you’ll need when getting started. The list below covers the basics that you’ll need to get started, but much will depend on your set-up and production output.

- Computer with design software.

- Printer for making the screens.

- Ink and film.

- Screens.

- Emulsion that hardens when exposed to UV light to create a stencil/screen.

- Drying racks for the screens when drying the emulsion.

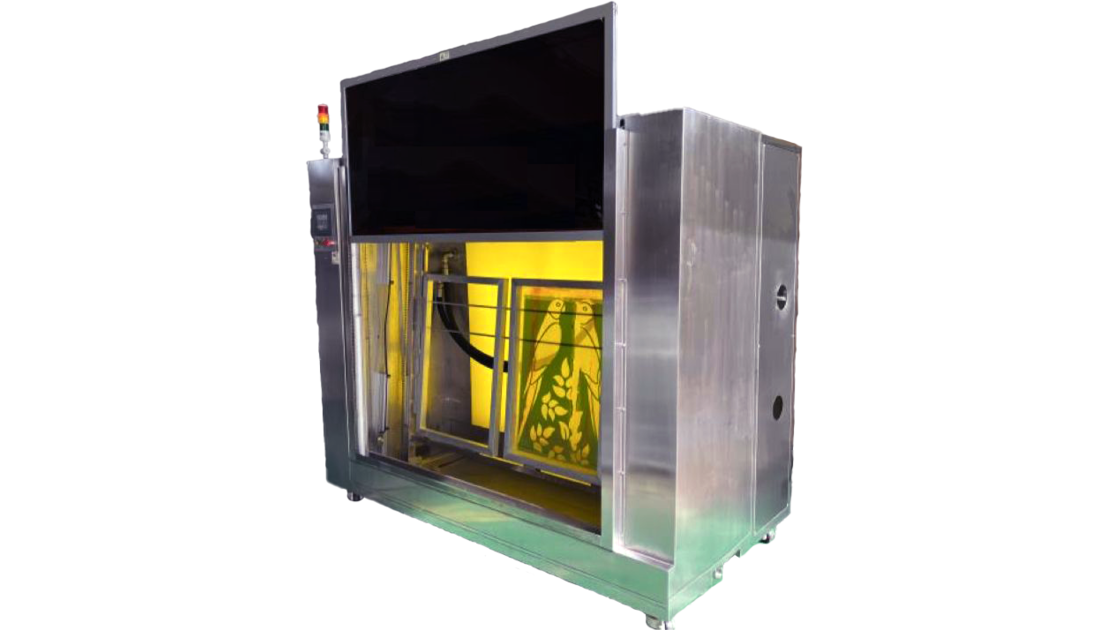

- Exposure unit to cure the stencils/screens.

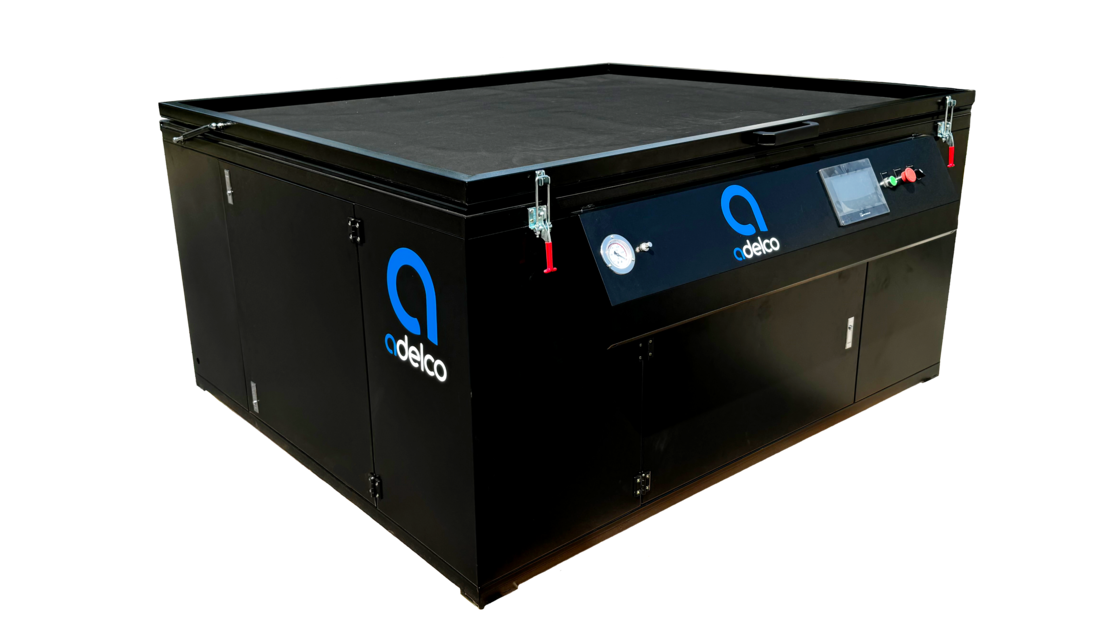

- Washout station to rinse and clean the screens.

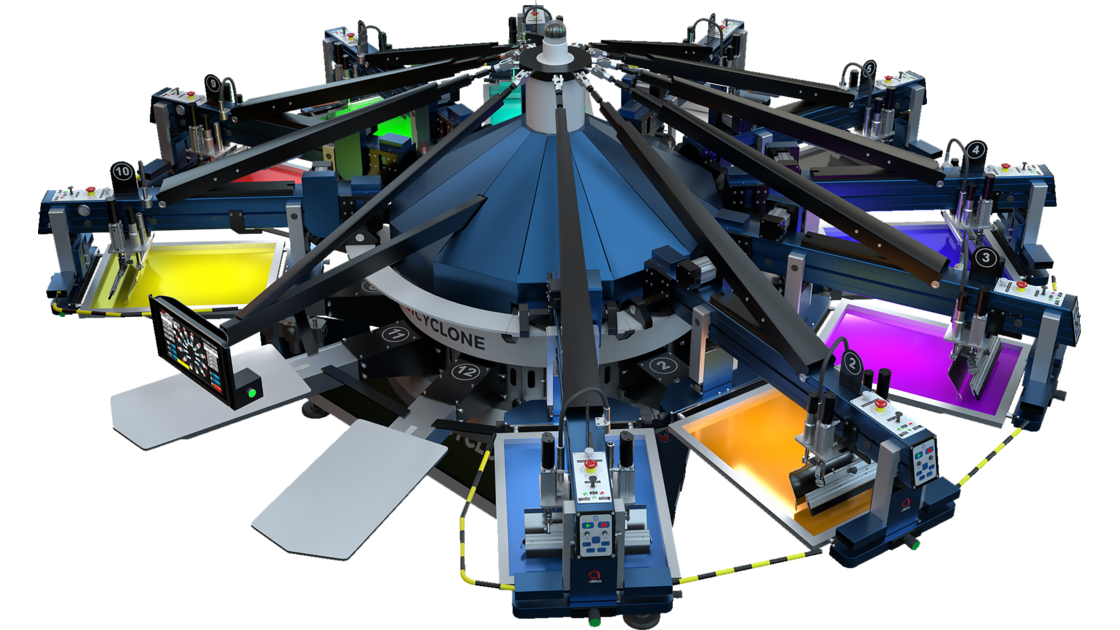

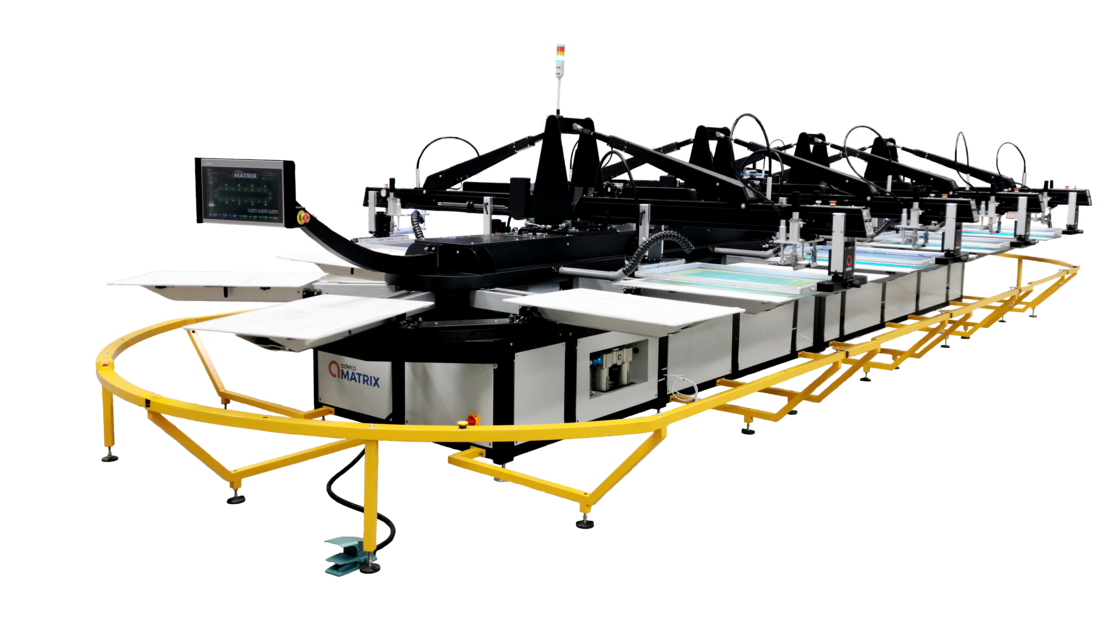

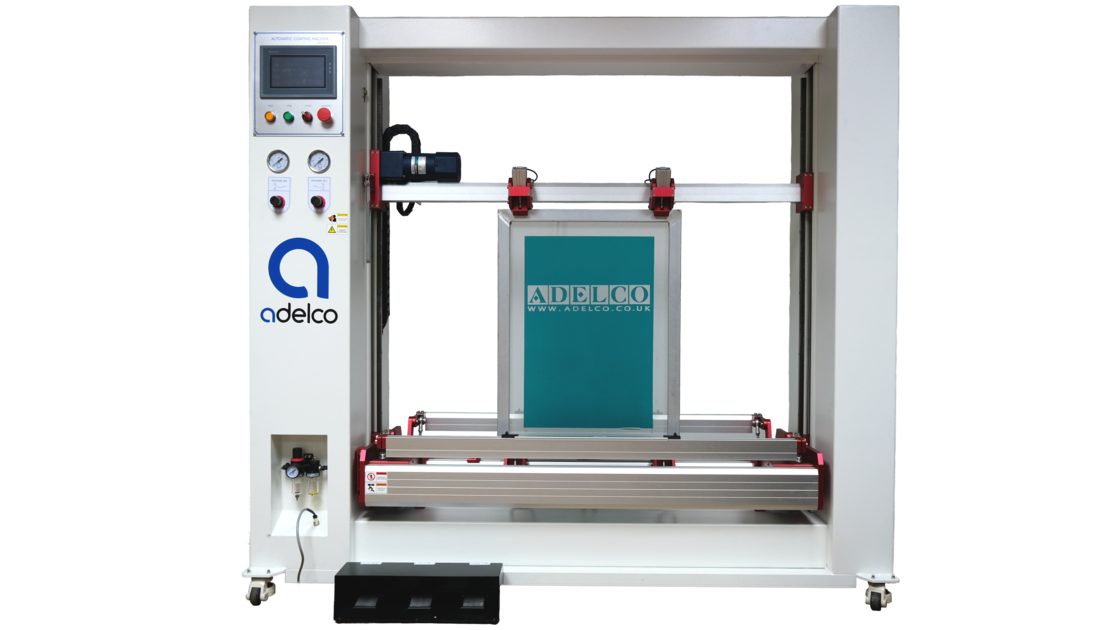

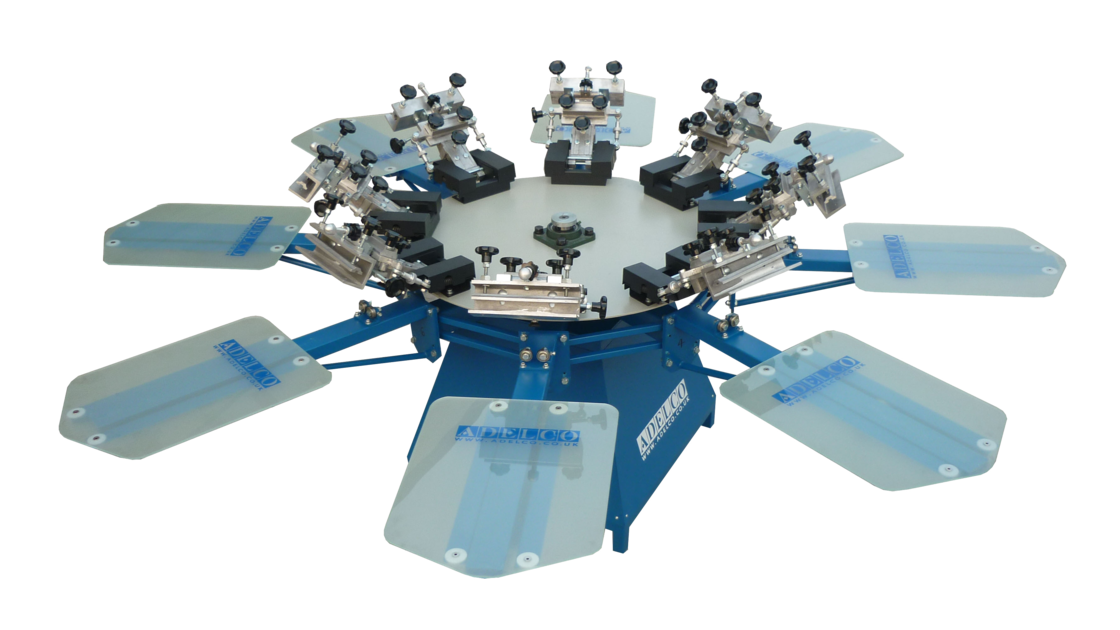

- Printing press, either auto or manual.

- Squeegees.

- Flash cure units, so you can print on top of base colours.

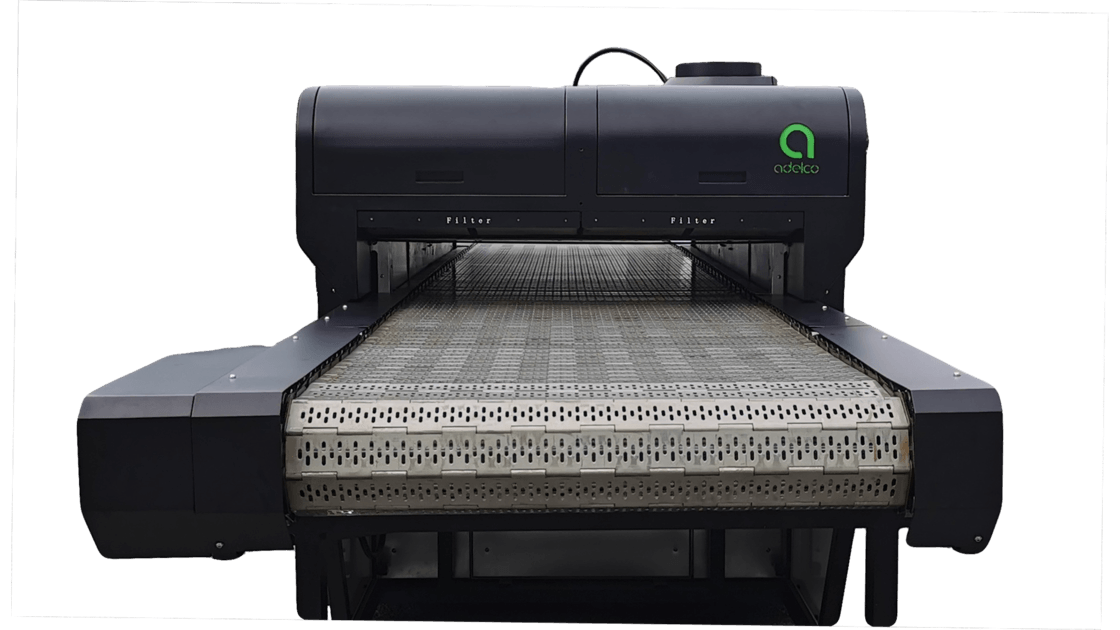

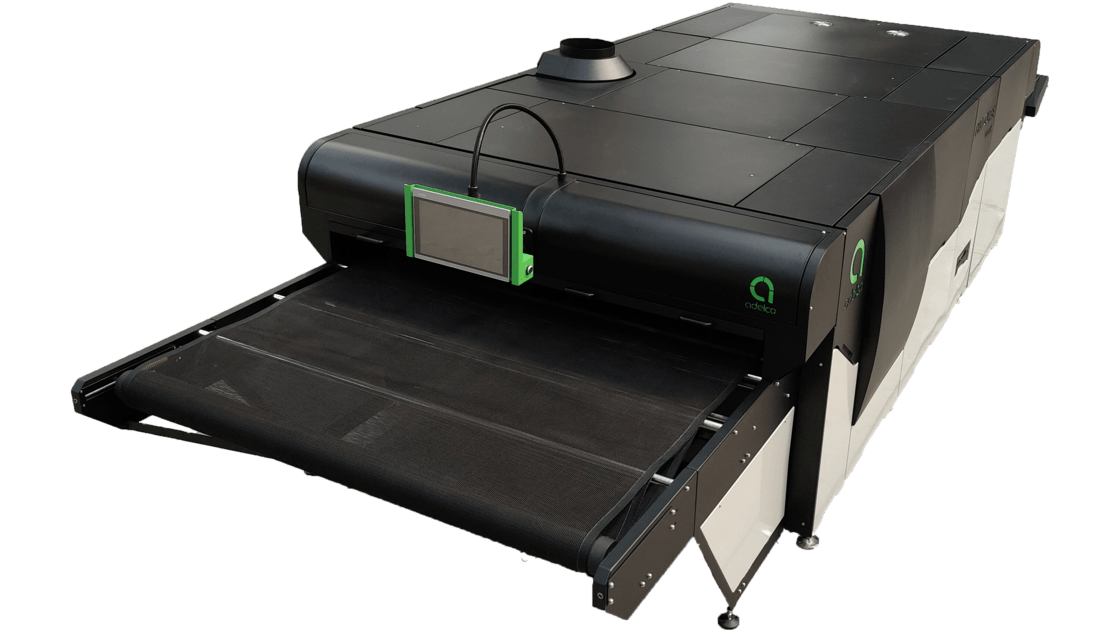

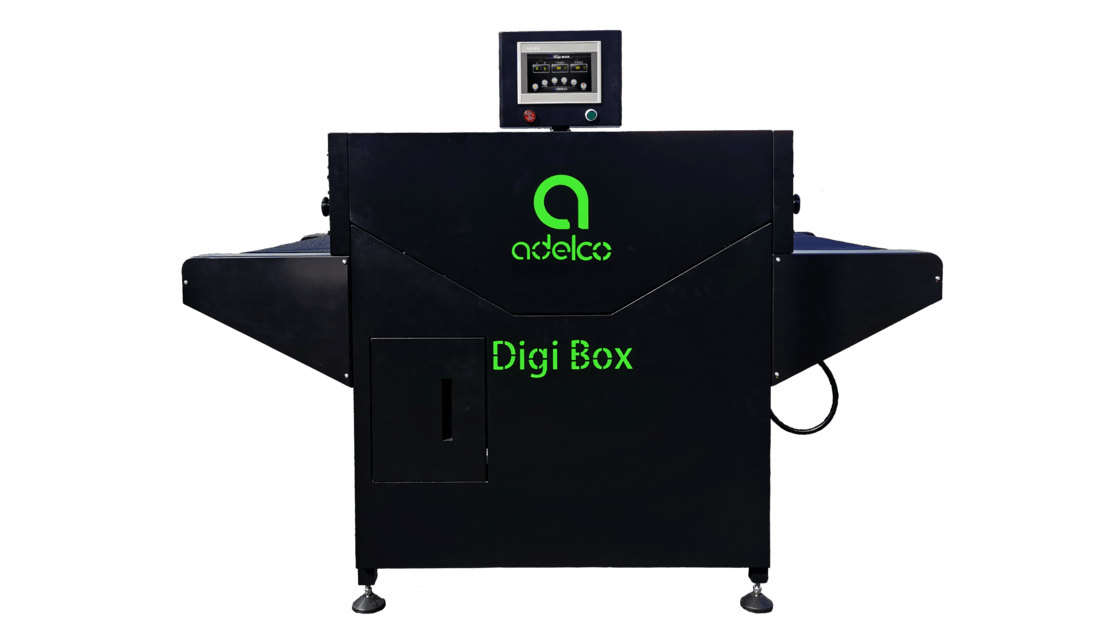

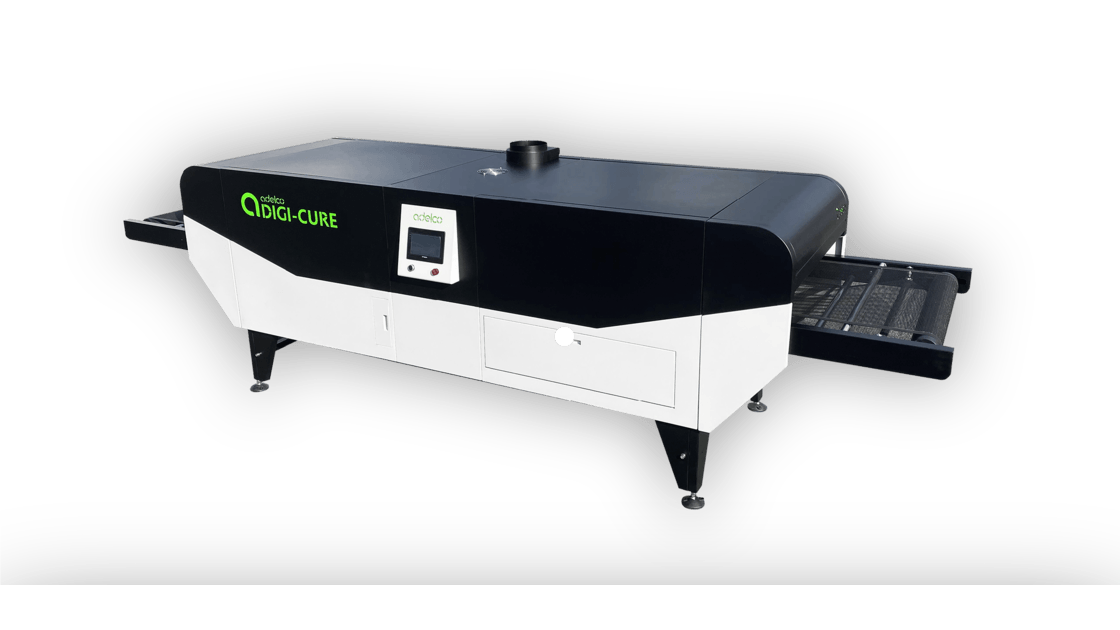

- Hot air Conveyor or drawer dryers to cure the print.

- What are the disadvantages of screen printing?

-

There are a few disadvantages to screen printing:

- This is a skilled practise and does have a steep learning curve.

- Screen printing needs a lot of space, the printing press, the clean out area alone adds up to a lot of real estate.

- Lots of cleaning up is required, this is not a mess free occupation.

- Limited art work placement. Compared to DTG.

- Does Screen Printing crack?

-

A screen print that has been printed well should not crack, fade or peel.

The most common reasons why a screen print may crack includes:

- The ink was too thick upon application

- The print wasn’t cured properly

- What is screen printing?

-

Screen printing in a nut shell involves creating a stencil (Artwork) on a mesh screen that is stretched on a frame. The garment lays underneath the screen and Ink is pushed through the mesh on to the fabric. This can be done by hand, or by an automatic printing press.

Each colour is pushed through separately on different screens to reach the finished design.

This is then heat treated to cure the ink, to stop any wash out. And create a lasting design.

- Does screen printing require heat?

-

Yes, screen printing does require heat to cure the print. The curing process heats the ink to a certain temperature which bonds the pigment, and evaporates the water in the ink. This ensures that the print is wash fast and permanent.

The best options to cure screen prints are:

- Tunnel dryers. This is by far the best option, although expensive, is worth the investment. resulting in an even distribution of time and heat.

- Flash Cures, this is a cheaper alternative, best for touch drying the ink before making another pass with another colour.

- Heat guns – better for small prints, takes time and can be hit and miss.

- How long do screen print transfers last?

-

Screen print transfers are a viable alternative to screen prints. As with other print methods, with the correct application and a good quality product the print will last as long as the garment does.

- Is screen printing the best for T shirts?

-

Both screen printing, transfers and DTG can all be used to a high standard on t shirts. The best method really does depend on the level of output, the nature of the design, and the nature of your business i.e. e-commerce will be more suited to DTG where as the most cost effective solution would be to use screen printing.

- How long does screen printing take to dry?

-

Using a hot air textile dryer and depending on the ink used, plastisol ink can take one minute to cure, water based inks take a like longer with two minutes.

Direct to garment prints can take up to 6 minutes in a hot air dryer.

- What is the best screen printing equipment?

-

A manual screen printer is a good starting point for most small printers. The majority start with 4-8 colours, which is ample to produce great designs as well as run two designs at the same time. For higher production runs, then investing in an automatic press will pay dividends with a greater ROI. It can do all the work an employee does in about 2 hours a day, and will be more consistent and reliable.

The more colours and stations you have, the higher amount of colours you can have on your print. As well as additional techniques, you can have on your print such as embossing, foild and flocking to name a few.

Look for a brand that’s innovative, reliable and has good support. Check out this link for our top of the range automatic machines: adelco.co.uk/screenprinting

- How many washes does screen printing last?

-

With a high quality print, and washed with care, screen prints should last the lifetime of the garment. The textile industry standard for T-shirt and other apparels is approx. 50 washings.

Product specific FAQs can be found on the product pages:

Adelco Reaper

Adelco Hybrid Digital

Adelco Cyclone

Adelco Matrix Oval Screen Printer

Adelco Ellipse Oval

Adelco Ellipse Sock Oval

Adelco All Over Oval

Universal Flash Cure

Hot Air Flash Cure

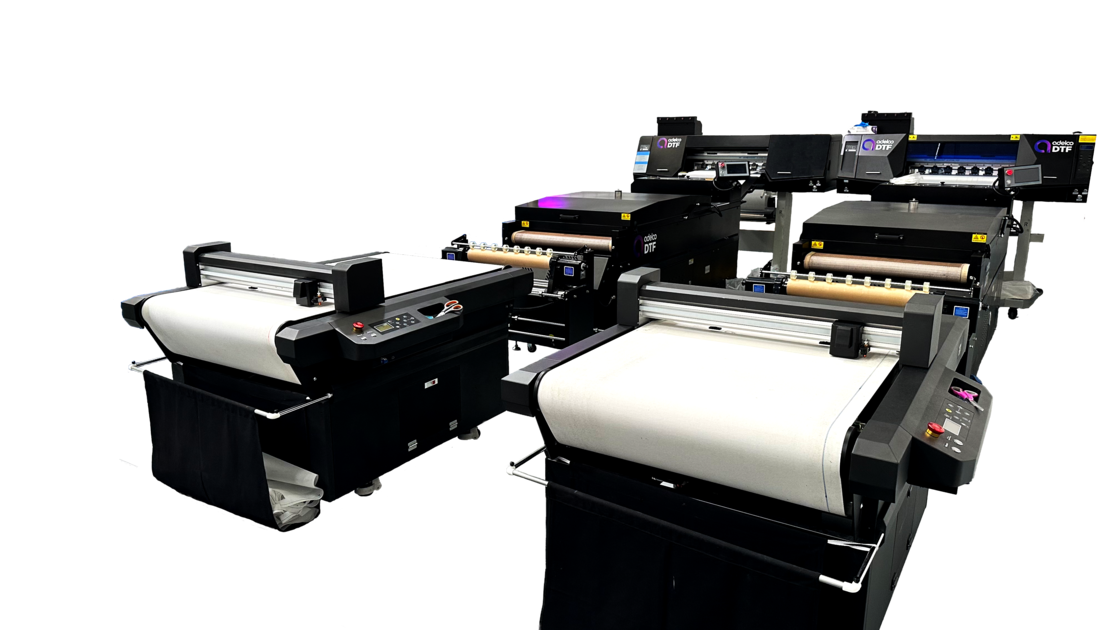

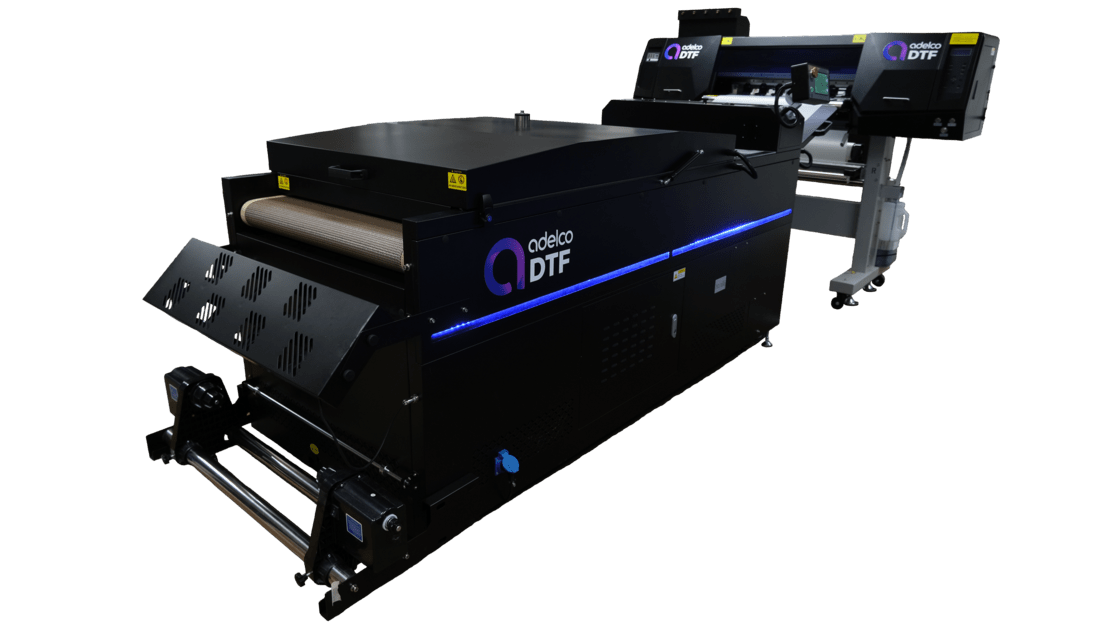

DTF Inline - Integrated Print & Cut Systems

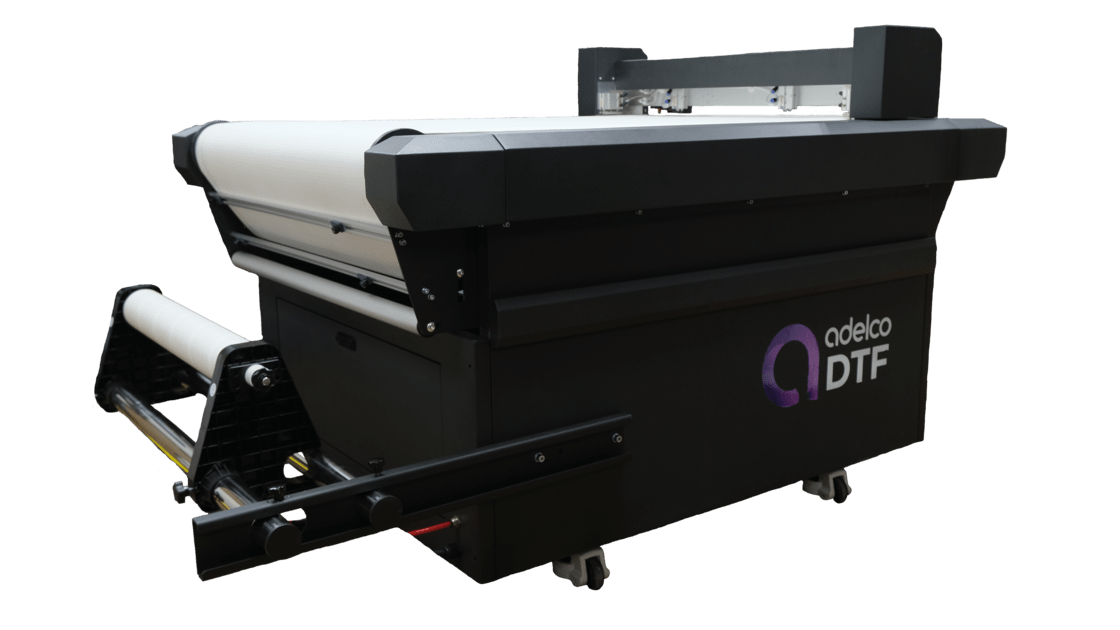

Adelco DTF Printer

Double-Sided UV DTF

DTF Cutter

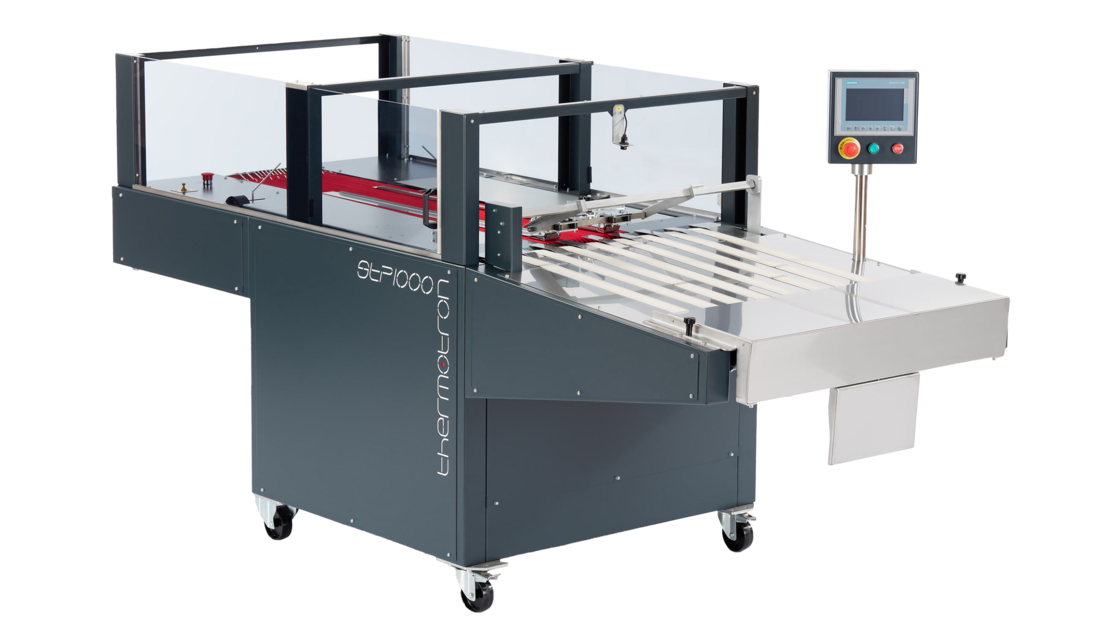

Folding Module - STP1000

Bagging module - PV40

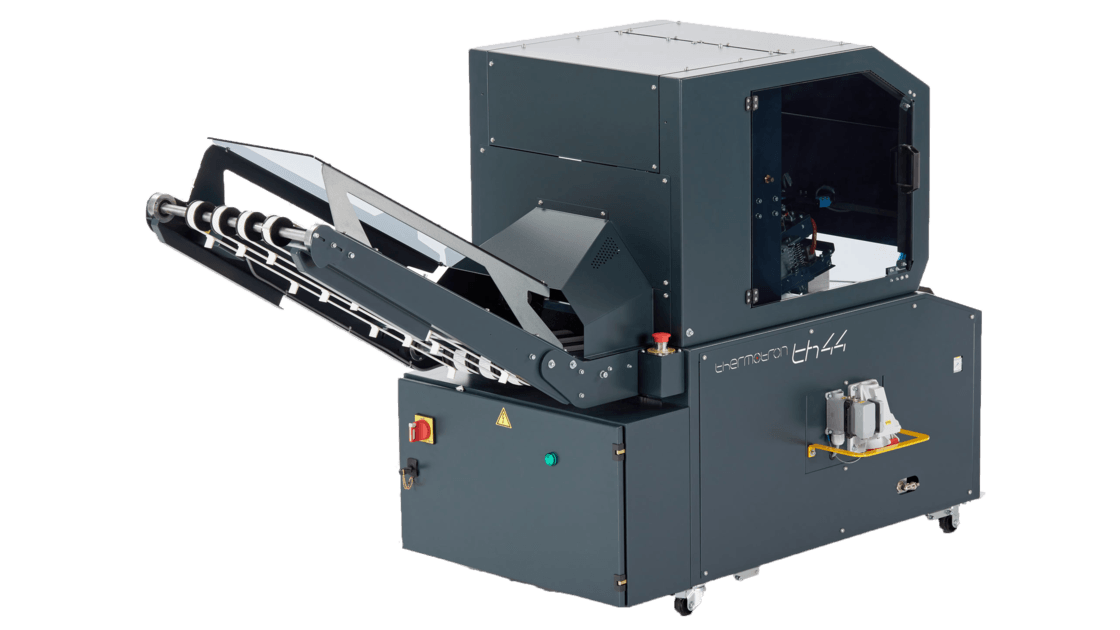

Automatic Heat Sealing Machine - TH44

Label machine - LD70

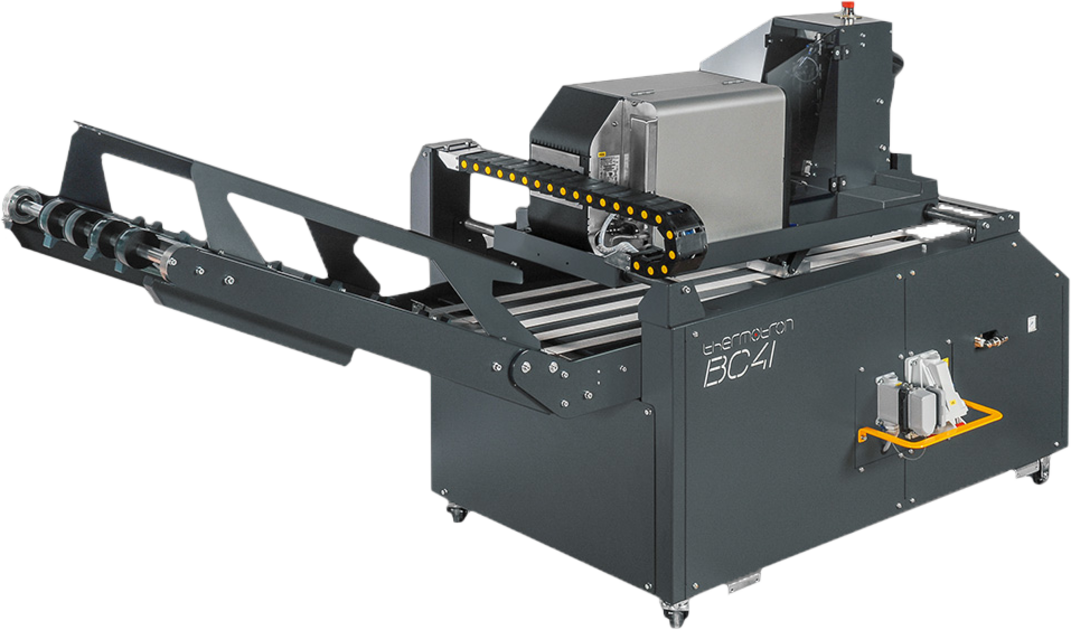

Barcode label printing module BC41

Sealing module - KL60

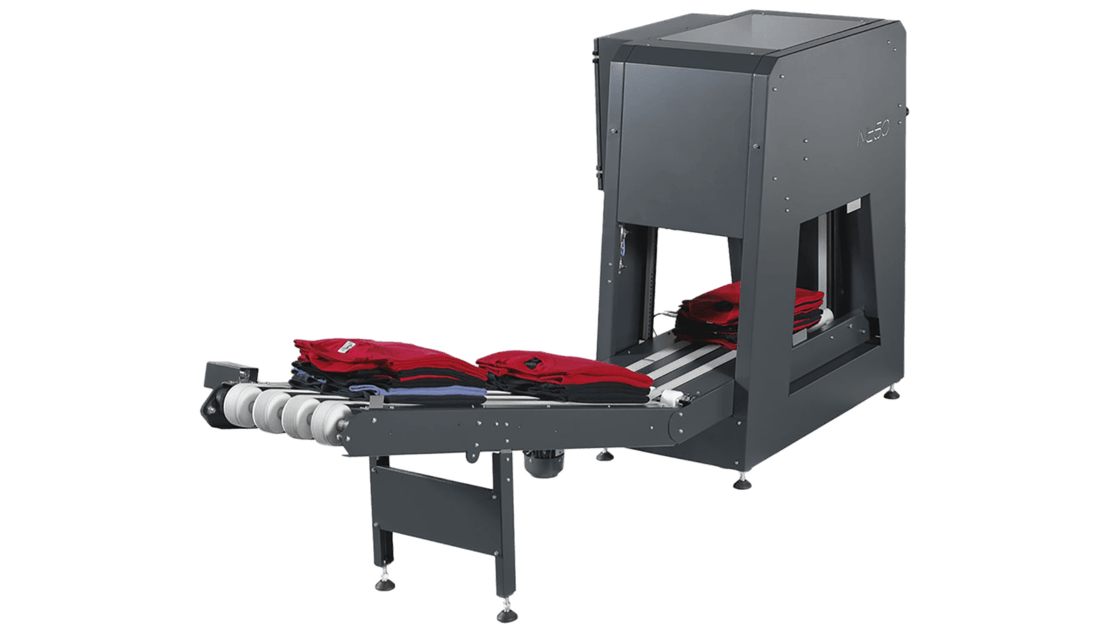

Stacking module - NT50

Folding and stacking machine - FX25 & FX25s

Adelco Screen Drying Cabinets

Screen Washing Solutions

Adelco Exposure Units

Adelco Heat Presses

Adelco Air Purifier

Adelco Stretching Solutions

Coating Systems

Adelco Manual Carousel

Adelco Ink Processor

Adelco InkPro

Adelco Laser V

Adelco Laser