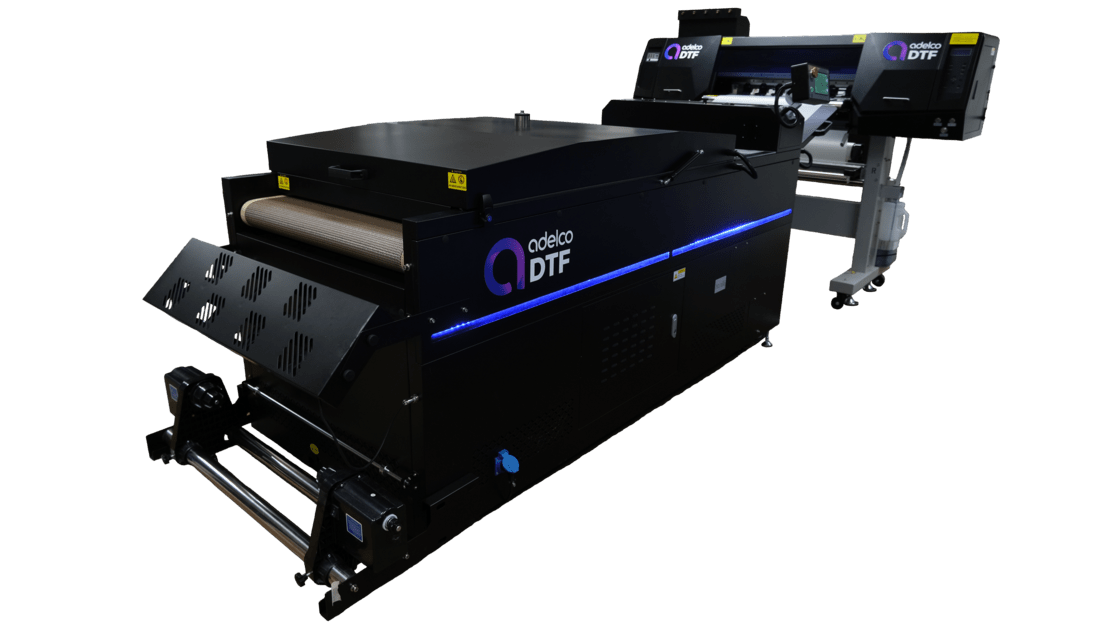

Adelco DTF Printer

The Most Completed In-Line Direct to Film Printer in the Market

Key features of the Adelco DTF Printer

- Four & Two Head Models Available - Options to fit specific printing needs.

- Eco-Friendly Water Based Pigment Ink - Sustainable and vibrant prints.

- Automatic Re-circulated Powder Shaker - Reduces waste and optimises resource use.

- In-line Drying Unit & Cooling Unit - Faster, more efficient printing.

- Auto Un-Wind and Re-Wind - Maintains consistent print quality.

- High-Definition Prints for Various Fabrics - Achieve remarkable print quality on a wide range of fabrics

- User-Friendly Interface - Easy operation with an intuitive touchscreen.

- High-Strength Aluminium Frame - Durable and long-lasting.

- Anti-Collision Device - Protects printing heads during extended operations.

- Advanced Heating Units - Consistent performance with intelligent heating tubes.

- No Weeding or Pre-Treatment Required - Simplifies the printing process.

Advanced Technologies in Adelco's DTF Printer

The Adelco DTF Printer provides cutting-edge Direct to Film (DTF) printing technology, delivering high-definition, durable prints on various fabrics. Perfect for businesses of all sizes, it offers precision, efficiency, and eco-friendly operations.

Why Choose Adelco DTF Printers?

- Eco-Friendly: Uses water-based inks for sustainable printing.

- Easy Integration: Compatible with existing screen printing setups.

- Comprehensive Support: Offers extensive training and ongoing customer service.

Adelco's Four-Headed DTF Printer, Automatic Re-Circulation Powder, and Dryer System

Our brand-new DTF printer is the fastest and highest-spec digital, direct-to-film printer in the market. It delivers high-definition prints in various fabrics and is supplemented with an in-line drying and cooler system.

Automated Re-Circulated Powder System

Our integrated re-circulating powder system minimises wastage and optimises resource utilisation, making your printing process more efficient.

Automated Powder Shaker

The integrated shaker ensures even powder distribution, resulting in cleaner and more precise print designs.

Precision Paper Pinch Roller

Experience remarkable printing speeds of up to 27m² per hour, thanks to our ultramodern pressing wheel that guarantees precision and stability.

Auto Un-Wind & Re-Wind

Our DTF system dynamically adjusts the film tension to accommodate varying print sizes, ensuring precise and consistent results.

Eco-Friendly Water Based Pigment Ink

Every ink we use is water-based, emphasising our commitment to eco-friendly practices in every print produced on our machines. This ensures a sustainable and environmentally conscious approach to printing.

Anti-collision Device

This feature safeguards the printing heads during extended operations, supplying an added layer of security and ensuring the longevity and reliability of the equipment.

Additional features of the DTF

- Advanced Heating Units - Five carbon fibre heating units ensure consistent performance

- No weeding needed - DTF requires no weeding and is made with just an inkjet printer

- User-Friendly Touchscreen Control - Streamline your operational experience with our intuitive touchscreen interface

- No Pre-Treatment Needed - Save time and resources with our advanced printing technology

Frequently Asked Questions (FAQs) about DTF Printers

- What Kind of Printer Do I Need for DTF?

-

A specialised DTF printer, such as the Adelco DTF Printer, is required for optimal results.

- What is a DTF Printer?

-

A DTF (Direct-to-Film) Printer is a specialised printer designed to print high-definition graphics directly onto a film, which can then be transferred to various fabrics.

- Is DTF Printing Better than Sublimation?

-

DTF printing offers superior fabric compatibility and print durability compared to sublimation.

- Can I Print DTF with Any Printer?

-

No, only certain printers can be converted to handle DTF printing effectively.

- How does a DTF Printer work?

-

A DTF Printer uses eco-friendly water-based pigment ink to print designs onto a film. The film is then coated with a powder adhesive and transferred to the fabric using heat and pressure.

- What are the key features of Adelco's DTF Printer?

-

Adelco's DTF Printer offers features like four and two head models, eco-friendly water-based pigment Ink, an automated re-circulated powder system, and more.

- What Fabrics Can I Print On with a DTF Printer?

-

Compatible with a wide range of fabrics, including cotton, silk, wool, denim, and Lycra.

- How fast is the Adelco DTF Printer?

-

The Adelco DTF Printer can achieve remarkable printing speeds of up to 27m² per hour.

- Is the ink used in DTF Printers eco-friendly?

-

Yes, Adelco's DTF Printers use water-based pigment ink, emphasising our commitment to eco-friendly practices.

- What is the Automated Re-Circulated Powder System?

-

This feature effectively recycles and reuses the powder, minimising wastage, and optimising resource utilisation.

- What is the Automated Re-Circulated Powder System?

-

This system minimises waste and optimises resource use by re-circulating unused powder.

- How do I maintain my DTF Printer?

-

Regular maintenance is required, including cleaning and software updates, supported by Adelco’s customer service.

- Where can I buy Adelco's DTF Printer?

-

You can make an inquiry on our website or contact our authorised dealers for purchasing options.

- Do you offer customer support for DTF Printers?

-

Yes, we provide comprehensive customer support, including installation, troubleshooting, and maintenance.

| Specs | 4 Head DTF Printer | 2 Head DTF Printer | 8 Head DTF Printer |

|---|---|---|---|

| Printing heads | 4 x Epson 13200 | 2 x Epson 13200 | 8 x EpsonI3200-A1 |

| Print Width | 600mm | 600mm | 1200mm |

| Resolution | 3200dpi | 3200dpi | 3200dpi |

| Colour | CMYK & White | CMYK & White | CMYK & White |

| Ink Type | Pigment Ink | Pigment Ink | Pigment Ink |

| Power Supply | 220V - 50HZ/60HZ (110V Option) 1500W | 220V - 50HZ/60HZ (110V Option) 1400W | 220V - 50HZ/60HZ (110V Option) 2200W |

| Speed | 4 pass: 27m2/h 6 pass: 17m2/h 8 pass: 13m2/ | 4 pass: 14m2/h 6 pass: 11m2/h 8 pass: 8m2/ | 4 pass: 55m2/h 6 pass: 36m2/h 8 pass: 27m2/ |

| Operation Enviroment | Temperature 18 - 30°C, Humidity: 40RH - 70RH | Temperature 18 - 30°C, Humidity: 40RH - 70RH | Temperature 15 - 30°C, Humidity: 40RH - 70RH |

| Machine Size | 1925 x 800 x 1667 mm | 1680 x 820 x 1430 mm | |

| Package Size | 2300 x 760 x 86 mm | 2370 x 750 x 650 mm | 2930 x 910 x 900 mm |

| Weight | 216KG | 160KG | 386kg |

| Belt Conveyor Automatic Re-Circulation Powder System | Yes | Yes | Yes |

| Applicable Film Width | 600mm | 600mm | 1200mm |

| Applicable Speed | 27m2/h | 14m2/h | 55m2/h |

| Platform Temperature | 75°C | 75°C | 75°C |

| Drying Temperature | 110°C | 110°C | 110°C |

| Media Type | PET transfer film | PET transfer film | PET transfer film |

| Media Transport | Belt guide system and dual powered take-up | Belt guide system and dual powered take-up | Belt guide system and dual powered take-up |

| Power Supply | 220V 50HZ/60HZ 6500W | 220V 50HZ/60HZ 6500W | 220V 50HZ/60HZ 12000W |

| Operation Environment | Temperature 18-30°C Humidity 40Rh-60RH | Temperature 18-30°C Humidity 40Rh-60RH | Temperature 18-30°C Humidity 40Rh-60RH |

| Heating | Intelligent 10 heating tubes infrared heating | Intelligent 5 heating tubes infrared heating | 10pcs x 805mm (800W/pcs) |

| Machine Size (Shaker) | 3122 x 1130 x 1105mm | 1920 x 1000 x 1210 | 3210 x 1510 x 1320mm |

| Package size (Shaker) | 2360 x 1150 x 1280 mm | 1850 x 1150 x 1280 mm | 2360 x 1790 x 1280 mm |

| Weight | 297KG | 270KG | 590Kg |

Make an enquiry now

Register your interest in the Adelco DTF Printer now. We guarantee you won't be disappointed.