How to Optimise Your Textile Printing Workflow with Integrated DTF Technology

Here’s how you can optimise your textile printing workflow using high-efficiency DTF printing systems.

In the competitive world of textile printing, optimising workflows is key to staying ahead. Direct-to-Film (DTF) printing has already revolutionised how businesses produce high-quality prints, but the introduction of integrated DTF technology takes it a step further. By adopting seamless DTF solutions, businesses can significantly enhance their DTF workflow optimisation efforts, improving speed, reducing errors, and increasing overall efficiency.

1. Streamlining Printing and Cutting with Integrated Systems

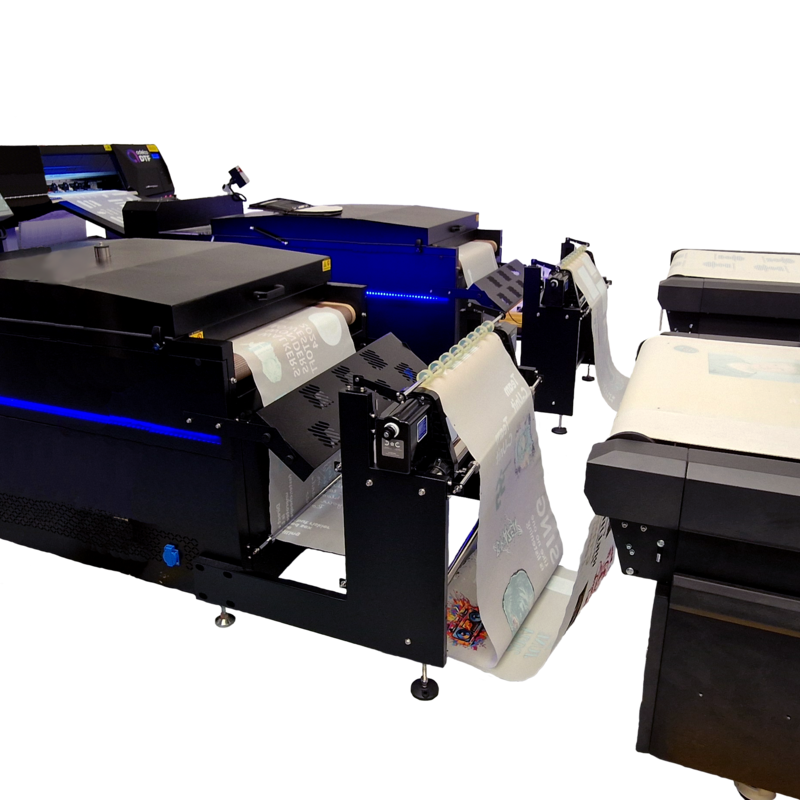

Traditional DTF setups require separate machines for printing, drying and cutting, which adds extra steps and increases the chances of misalignment and wasted materials. By integrating these processes, you can streamline your production workflow, removing the need for manual interventions between printing and cutting.

With an integrated DTF Inline Integrated Print & Cut System, you’ll combine all steps into one seamless process, increasing speed and accuracy. This setup not only reduces production time but also ensures precision, minimising errors and material waste. The faster workflow allows businesses to take on more jobs while maintaining consistent, high-quality output.

2. Automation and Error Reduction

Seamless DTF solutions automate significant parts of the workflow, reducing the chances of human error. Automated DTF machines handle printing and cutting, ensuring that every design is perfectly aligned before cutting. This eliminates the need for manual interventions, often leading to mistakes and inefficiencies.

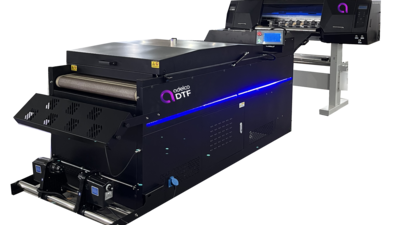

Using automated systems like the Adelco DTF Printer ensures that your designs are printed accurately and consistently, which is crucial when managing large orders with intricate designs. Automation not only enhances the quality of the final product but also helps your team focus on other essential aspects of the business.

3. Improve Workflow Speed for High-Volume Orders

As demand increases, especially for custom apparel, your printing system needs to handle high volumes without compromising quality or speed. By adopting high-efficiency DTF printing systems, such as Adelco’s DTF Cutter, businesses can manage large production runs with greater efficiency.

High-speed printers and cutters ensure that even large-scale orders can be completed in a fraction of the time it would take using traditional setups. This allows you to accept more orders and deliver them faster, ensuring customer satisfaction and boosting your bottom line.

4. Maximising Space Efficiency

For smaller businesses or workshops with limited space, optimising workflow often means making the most of the available space. Integrated systems, like Adelco’s DTF Printer and DTF Inline Integrated Print & Cut Systems, combine multiple processes into one machine, freeing up valuable floor space for other tools or production lines.

This space-saving benefit not only improves the overall efficiency of your workspace but also allows you to scale production without the need for additional equipment or expanded premises.

5. Diversifying with UV DTF Technology

To truly optimise your DTF workflow and open up new opportunities, consider expanding beyond textiles into other surfaces. UV DTF systems allow you to print on a wide range of non-fabric materials such as glass, plastic, and metal, helping your business offer a more diverse product range.

Diversification can improve workflow efficiency by allowing you to consolidate production for various product types in one location. With UV DTF systems, you can tap into new markets while maintaining the same streamlined, high-efficiency processes that you use for textiles.

6. Consistency in Quality and Results

Optimising your DTF workflow isn’t just about speed—it’s also about maintaining consistent quality across all prints. With integrated DTF technology, every step of the process, from printing to cutting, is tightly controlled, ensuring that each product meets the highest standards.

Adelco’s DTF Printer, for example, delivers high-quality prints every time, using advanced ink technology to ensure vibrant, durable designs. Coupled with the precision of DTF Cutters, your workflow will produce consistently high-quality products, no matter the complexity of the design or size of the order.

Adopting integrated DTF technology offers businesses the opportunity to streamline and optimise their textile printing workflows. Whether you’re looking to increase production speed, reduce errors, save space, or diversify your product offerings, seamless DTF solutions can help achieve these goals. By investing in high-efficiency DTF printing systems, such as those offered by Adelco, your business can stay ahead in the competitive textile printing industry.

Want to take your textile printing to the next level? Contact Adelco today for a free consultation and discover how our DTF workflow solutions can transform your production process. Or, book a demo to see our state-of-the-art equipment in action!

Frequently Asked Questions (FAQs)

- What is integrated DTF technology?

-

Integrated DTF technology combines the printing, drying and cutting processes into one seamless system. This eliminates the need for multiple machines, streamlines production, and ensures that designs are printed and cut with perfect alignment.

- How can integrated DTF systems improve workflow efficiency?

-

By automating the transition between printing and cutting, integrated DTF systems reduce manual interventions, speed up production, and reduce errors. This improves overall efficiency, particularly for high-volume orders.

- Is DTF printing suitable for businesses with limited space?

-

Yes, Adelco’s integrated DTF systems, such as the DTF Printer and DTF Inline Integrated Print & Cut Systems, are space-saving solutions that allow businesses to optimise their production setup in smaller workspaces.

- Can DTF technology be used on non-fabric surfaces?

-

Yes, UV DTF systems can print on a variety of non-fabric materials such as glass, metal, and plastic, providing businesses with the opportunity to diversify their product offerings.

- How does automation reduce errors in DTF printing?

-

Automation in DTF machines ensures precise alignment between the printing and cutting processes, reducing the risk of misalignment or other manual errors. This results in consistent, high-quality prints with minimal wastage.

Recent articles

Why Precision Matters: The Role of Accurate Cutting in DTF Printing

Eco-Friendly Printing: How Integrated DTF Systems Reduce Waste