Why Precision Matters: The Role of Accurate Cutting in DTF Printing

In the world of garment printing, precision is everything

While Direct-to-Film (DTF) printing offers a versatile, high-quality method for producing vibrant designs on various fabrics, it’s the cutting process that often separates a good print from a great one. For those looking to achieve professional results, understanding the importance of DTF precision cutting is crucial.

In this article, we’ll explore why accurate DTF printing relies on precision cutting, how print-cut integration enhances production, and the essential role it plays in delivering high-quality results for your business.

The Importance of Precision in DTF Printing

DTF printing is all about transferring intricate designs onto fabric. While the printing process itself delivers high-quality prints, it’s the cutting process that ensures your design looks polished and professional once applied. Poor cutting can ruin even the most vibrant print, making precision cutting an integral part of the DTF printing process.

For example, when printing intricate designs with detailed edges, or custom shapes, accurate cutting becomes crucial to avoid cutting into the design or leaving excess film, both of which can result in unprofessional final products.

Key reasons why DTF precision cutting is critical:

- Clean, Professional Results: Accurate cutting ensures that your design is crisp and clean, with no unsightly edges or leftover film around the design.

- Waste Reduction: Precise cutting minimises material waste by ensuring the cut aligns perfectly with the printed design, which is especially important when working with expensive transfer films.

- Consistency: When you're handling bulk orders or custom jobs, precision cutting ensures that every product maintains a consistent quality, boosting customer satisfaction and brand reputation.

What Is DTF Precision Cutting?

DTF precision cutting involves the accurate trimming of printed designs on transfer film before they are applied to fabric using a heat press. This step is essential because it defines the final appearance of the print on the garment.

The cutting process must perfectly align with the printed design, especially if you’re working with intricate shapes or borders. Manual cutting often leads to uneven edges or errors, which is why automated print-cut integration is key to producing accurate results consistently.

Manual vs. Automated Cutting: The Case for Automation

DTF precision cutting involves the accurate trimming of printed designs on transfer film before they are applied to fabric using a heat press. This step is essential because it defines the final appearance of the print on the garment.

The cutting process must perfectly align with the printed design, especially if you’re working with intricate shapes or borders. Manual cutting often leads to uneven edges or errors, which is why automated print-cut integration is key to producing accurate results consistently.

Manual vs. Automated Cutting: The Case for Automation

Many new businesses or hobbyists might start with manual cutting using scissors or basic tools. While this might work for simpler designs or small-scale operations, it quickly becomes inefficient and prone to errors, especially when dealing with larger volumes or intricate patterns. Manual cutting can result in:

- Inconsistent Results: Slight hand movements can cause shifts, leading to inconsistent cutting.

- Time-Consuming: For large orders or complex designs, manual cutting is slow and laborious, limiting production speed.

- Material Waste: Errors in cutting can lead to wasted transfer film or garments.

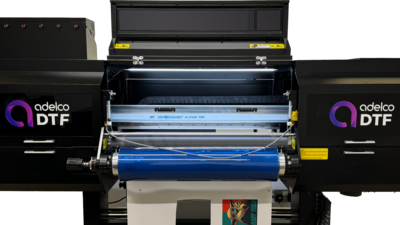

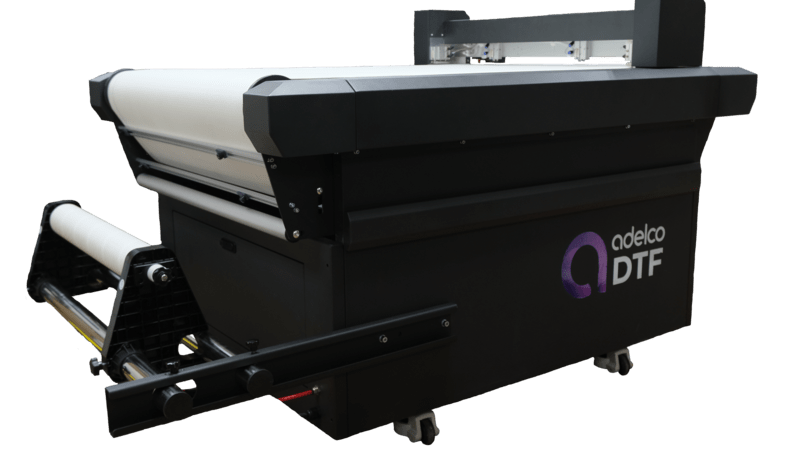

On the other hand, automated systems like Adelco’s DTF Inline Integrated Print & Cut Systems solve these issues by integrating the printing and cutting processes into one seamless workflow. This offers:

- Precise, Consistent Results: Automated systems ensure that every cut is perfectly aligned with the design.

- Faster Production: Automation significantly reduces production time, allowing you to fulfil larger orders more efficiently.

- Error Reduction: Machines eliminate the risk of human error, ensuring each design is cut precisely every time.

How Print-Cut Integration Improves Accuracy

Print-cut integration combines the printing and cutting processes into one cohesive system, allowing both tasks to be completed in perfect synchronisation. For DTF printing, this means that as soon as the design is printed on the transfer film, the machine automatically cuts the design to match its shape and outline.

Adelco’s DTF Cutter ensures that each cut is as precise as the print, resulting in clean, professional-looking garments with minimal wastage. This integration between the printing and cutting stages not only improves accuracy but also boosts production efficiency by removing the need for manual intervention.

Benefits of print-cut integration include:

- Seamless Workflow: Integrating the processes reduces handling time and eliminates the need for manual adjustments.

- Improved Precision: Machines cut exactly where needed, ensuring designs are crisp and aligned correctly.

- Increased Production Speed: By handling both tasks automatically, your business can take on more orders without sacrificing quality.

The Role of Cutting in Specialised DTF Applications

If your business plans to diversify its offerings, such as working with non-fabric materials using UV DTF systems, precision cutting becomes even more crucial. These systems allow for printing on surfaces like glass, metal, and plastic, making clean cuts essential to ensure the print fits seamlessly on these surfaces.

Furthermore, when dealing with multi-layer or multi-colour designs, accurate cutting ensures each layer aligns perfectly, which is essential for creating a professional final product.

Tips for Achieving Precision in DTF Cutting

- Invest in a High-Quality Cutter

-

If you’re serious about maintaining precision, investing in a reliable, automated DTF Cutter or an integrated print-cut system will make all the difference.

- Ensure Proper Calibration

-

Always check that your cutting machine is properly calibrated to avoid misalignment between the print and cut. Calibration issues can lead to small but noticeable mistakes in the final product.

- Use High-Quality Transfer Film

-

The quality of your transfer film also affects the precision of your cuts. High-quality film is easier to work with and ensures smoother cuts, reducing the likelihood of fraying or rough edges.

- Test Designs Before Large Runs

-

Always test your designs on a small scale before committing to large production runs. This ensures the cutting alignment is perfect and allows for any adjustments before you print in bulk.

Precision Cutting Is Essential for Professional DTF Printing

In DTF printing, precision cutting is the final touch that transforms a printed design into a professional-quality product. Whether you’re working with simple designs or complex, multi-colour prints, accurate cutting is essential for delivering consistent, high-quality results.

By integrating cutting into your printing workflow using tools like Adelco’s DTF Inline Integrated Print & Cut Systems, you can ensure that every design is cut perfectly, improving production speed, reducing waste, and enhancing the quality of your final products.

Precision matters—and when it comes to DTF printing, it’s what sets the professionals apart from the amateurs.

Explore Adelco’s Full Range of DTF Workflow Solutions:

Recent articles

Eco-Friendly Printing: How Integrated DTF Systems Reduce Waste

A Beginner’s Guide to DTF Printing and Cutting: What You Need to Know