Eco-Friendly Printing: How Integrated DTF Systems Reduce Waste

The printing industry is turning to more eco-friendly methods to reduce waste and minimise environmental impact.

Traditional printing methods often generate significant waste, but Direct-to-Film (DTF) printing offers a greener alternative. Using integrated DTF systems, businesses can drastically reduce waste, lower energy consumption, and adopt sustainable printing solutions. This article explores the benefits of eco-friendly DTF printing, how it reduces waste, and why it’s a smart choice for companies seeking sustainable printing solutions.

The Environmental Impact of Traditional Printing Methods

Traditional garment printing methods like screen printing and Direct-to-Garment (DTG) produce substantial waste. Key issues include:

- Excessive Ink Use: Screen printing often requires large amounts of ink, much of which goes to waste.

- High Water Consumption: Screen printing processes demand large amounts of water for cleaning screens and mixing inks.

- Pre-Treatment Chemicals: DTG printing uses chemicals to pre-treat fabrics, contributing to chemical waste.

- Energy Inefficiency: Older printing equipment consumes more energy, contributing to a larger carbon footprint.

| Aspect | DTF Printing | Screen Printing | Direct-to-Garment (DTG) |

| Ink Waste | Minimal waste due to precision | High ink wastage | Some excess ink |

| Water Usage | None | High (for screen cleaning, mixing) | Low (only for fabric pre-treatment) |

| Pre-treatment Chemicals | None | None | Required for many fabrics |

| Transfer Film Waste | Minimal | N/A | N/A |

| Energy Consumption | Low (modern systems are efficient) | High (requires drying equipment) | Medium |

| Production Waste | Minimal (precise print cut integration) | Moderate (manual adjustments) | Low |

Let’s take a closer look at how DTF printing compares to these traditional methods in terms of waste reduction and environmental impact:As seen in the table, DTF printing offers clear advantages in reducing ink waste, eliminating water usage, and minimising energy consumption compared to traditional methods. This makes DTF systems more sustainable and eco-friendly for businesses.

How DTF Printing Reduces Waste

DTF printing stands out for its efficient use of resources and minimal waste production. Here’s how eco-friendly DTF printing helps businesses reduce waste and become more sustainable:

- Precise Ink Usage

-

Traditional printing methods often result in excessive ink wastage due to overspray or incorrect estimates of required ink. In contrast, DTF printing uses only the exact amount of ink needed to transfer designs to fabrics. This efficiency is made possible through Adelco’s DTF Printer, which ensures precision in the printing process. As a result, businesses using DTF technology can significantly reduce ink wastage.

- Elimination of Pre-Treatment Chemicals

-

Unlike Direct-to-Garment (DTG) printing, which often requires pre-treatment chemicals to prepare fabrics for printing, DTF printing does not need pre-treatment. This eliminates the use of potentially harmful chemicals and reduces waste associated with chemical disposal. By skipping this step, businesses not only save time but also contribute to a cleaner and more eco-friendly production process.

- Accurate Cutting Minimises Waste

-

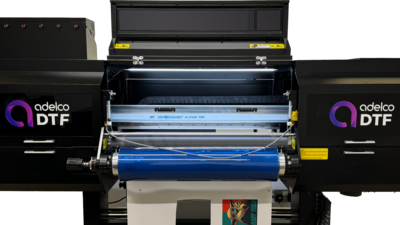

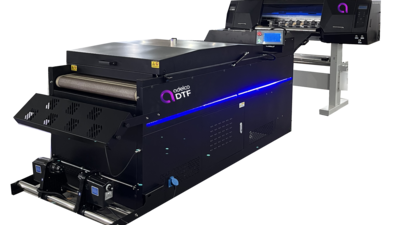

Precision is crucial in reducing waste, especially when handling intricate or custom designs. Print-cut integration, like that found in Adelco’s DTF Inline Integrated Print & Cut Systems, ensures that the cutting process perfectly matches the printed design. This accuracy reduces the amount of transfer film left unused and minimises errors that can lead to material wastage.

For businesses aiming to streamline their production processes, automated cutting not only ensures consistency but also cuts down on excess materials—further driving waste reduction in printing.

- Lower Energy Consumption

-

Traditional printing methods like screen printing often require additional drying equipment, which increases energy consumption. In contrast, modern DTF printers are more energy-efficient, reducing overall energy use. By investing in energy-efficient machines, such as Adelco’s DTF printers, businesses can lower their energy costs while reducing their environmental impact.

With integrated DTF systems, businesses can reduce production time and energy use by automating processes that traditionally required manual intervention or additional energy-consuming equipment.

- Reduced Material Waste with Integrated Systems

-

Integrated DTF print-cut systems automate both the printing and cutting processes, ensuring that materials are used efficiently and waste is minimised. The precise coordination between the printing and cutting stages reduces the chances of errors, eliminating the need for reprints and further waste. This makes integrated systems a key element of eco-friendly DTF printing.

Sustainable Ink and Transfer Film Options

To further enhance the environmental benefits of DTF printing, businesses can opt for eco-friendly inks and transfer films. Water-based inks are a sustainable choice, as they contain fewer harmful chemicals and are biodegradable. In addition, some businesses are adopting recyclable or compostable transfer films to reduce plastic waste during the production process.

By incorporating these eco-friendly materials into your DTF workflow, you can reduce your environmental impact while maintaining the high-quality standards expected from modern printing methods.

The Long-Term Benefits of Eco-Friendly DTF Printing for Businesses

Choosing eco-friendly DTF printing isn’t just beneficial for the environment—it’s also a smart business move. Reducing waste, energy consumption, and material usage can lead to long-term cost savings, making your business more efficient and profitable over time.

Additionally, as consumers become more environmentally conscious, businesses that prioritise sustainability are likely to attract a wider customer base. Today’s eco-conscious consumers often seek out brands that align with their values, and adopting sustainable printing solutions can help position your business as a leader in sustainability.

Why Eco-Friendly DTF Printing is the Future

As the demand for sustainable printing solutions grows, businesses are turning to DTF technology to reduce waste, lower energy consumption, and minimise their environmental impact. With the help of integrated DTF systems like Adelco’s DTF Inline Integrated Print & Cut Systems, companies can streamline their operations while making a positive impact on the environment.

For businesses committed to sustainability, eco-friendly DTF printing offers an efficient, cost-effective way to reduce waste, improve energy efficiency, and appeal to eco-conscious consumers.

Explore Adelco’s Sustainable Printing Solutions:

Recent articles

Why Precision Matters: The Role of Accurate Cutting in DTF Printing

A Beginner’s Guide to DTF Printing and Cutting: What You Need to Know