A Beginner’s Guide to DTF Printing and Cutting: What You Need to Know

For anyone stepping into the world of garment printing, Direct-to-Film (DTF) printing offers a versatile and efficient way to create vibrant, durable designs on

If you're new to DTF printing basics or are looking for start-up printing solutions, this guide will walk you through everything you need to know about DTF printing and DTF cutting.

Why DTF Printing is Ideal for Start-Ups

In today’s competitive printing landscape, businesses—especially start-ups—need cost-effective solutions that deliver high-quality results across a variety of fabric types. DTF printing stands out as an ideal choice for new businesses due to its versatility, ease of use, and scalability.

Here’s why DTF printing is a great option for start-ups

- Low Initial Investment

-

Compared to other printing methods, such as screen printing or Direct-to-Garment (DTG), DTF printing equipment is generally more affordable. You don’t need a huge upfront investment to get started, making it an excellent start-up printing solution.

- Versatile Fabric Printing

-

Whether you're printing on cotton, polyester, or even blends, DTF printing handles it all without the need for pre-treatment, unlike DTG. This flexibility allows you to cater to a broader market.

- No Pre-Treatment Required

-

Unlike other methods, DTF eliminates the need for time-consuming fabric pre-treatment, speeding up your production process.

What is DTF Printing?

Direct-to-Film (DTF) printing involves transferring designs onto a specialised film and using heat to bond the design to a fabric. One of the major advantages of DTF printing is its ability to print on almost any fabric, making it a versatile option for any start-up.

DTF vs. Other Methods:

- DTG is limited to cotton and requires pre-treatment, whereas DTF works on a wide range of fabrics, including polyester, blends, and even non-textile surfaces with UV DTF Systems.

- Screen printing is cost-effective for bulk orders but requires high setup costs, whereas DTF is suitable for both small and large batches, offering flexibility in order size.

Equipment Needed for DTF Printing

To start DTF printing, you’ll need the following essential equipment:

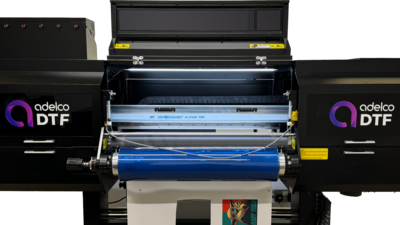

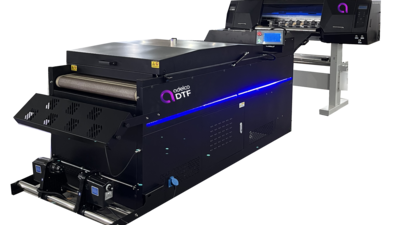

- DTF Printer: A specialised printer that can handle the printing of designs on transfer film. Adelco’s DTF Printer is an excellent choice for producing high-quality, vibrant prints on a variety of fabrics.

- Heat Press: This is crucial for bonding the design to the fabric. A good heat press ensures the transfer is smooth and durable.

- DTF Cutter: For intricate designs or custom shapes, you’ll need a DTF Cutter to precisely cut around your designs, providing a polished final product.

- Transfer Film and Adhesive Powder: Specialised transfer film is essential, as is adhesive powder, which ensures that the ink bonds to the fabric.

- DTF Software: DTF printers come with software to help prepare your designs and manage colour profiles. The right software ensures that you get accurate and consistent prints.

Step-by-Step: How DTF Printing Works

Here’s a step-by-step guide to the DTF printing process, broken down into simple, easy-to-follow steps:

- Print the Design

-

Using a DTF printer, print your design onto a specialised DTF transfer film. The design is printed in reverse, starting with white ink, which acts as a base, followed by coloured layers.

Pro Tip: Make sure your printer is calibrated correctly to ensure vibrant colours and crisp details.

- Apply Adhesive Powder

-

Once the design is printed, a layer of hot-melt adhesive powder is applied to the printed film. This powder bonds the ink to the fabric during the heat press stage.

Pro Tip: Ensure the powder is spread evenly to avoid patchy transfers.

- Cure the Transfer

-

The adhesive powder is activated by heating the transfer, either with a heat press or in an oven. This step ensures that the powder melts and bonds to the ink, preparing it for transfer to the fabric.

Pro Tip: Be careful with heat settings to avoid over-curing, which can affect the quality of the final print.

- Heat Press the Transfer

-

Place the transfer film onto the garment and use a heat press to bond the design to the fabric. The heat activates the adhesive, ensuring that the design adheres permanently to the fabric.

Pro Tip: Use the right temperature and pressure settings to ensure a durable bond.

- Peel and Final Press

-

Once the design has cooled, peel off the transfer film to reveal your design. For added durability, press the garment again for a few seconds.

Pro Tip: Allow the transfer to cool completely before peeling to ensure the design adheres correctly.

Common Mistakes to Avoid in DTF Printing

If you're a beginner, it’s important to know the pitfalls of DTF printing. Here are some common mistakes to avoid:

- Incorrect Heat Settings: Too much or too little heat can affect the bonding process. Always follow the recommended settings for your heat press and fabric type.

- Uneven Powder Application: Uneven adhesive powder can cause patchy prints or designs that don’t stick properly.

- Rushing the Cooling Process: Make sure the design has completely cooled before peeling the transfer film. Peeling too early can ruin the print.

Why DTF Cutting Is Essential for Professional Results

DTF cutting ensures that your prints have a clean, professional finish. For more intricate designs, precise cutting around the design is crucial. Manual cutting can be time-consuming and prone to errors, so investing in a DTF Cutter can significantly improve your workflow efficiency.

For those looking to streamline the printing and cutting process, Adelco’s DTF Inline Integrated Print & Cut Systems combine both functions in one machine, saving time and reducing errors.

Why DTF Is Perfect for Growing Businesses

Not only is DTF printing perfect for start-ups, but it’s also highly scalable. As your business grows, you can easily handle larger orders and a wider variety of fabrics without needing to drastically change your equipment or setup.

If you plan to expand into non-fabric items like glass or plastic, UV DTF Systems offer a unique opportunity to diversify your product line, providing another revenue stream as your business scales.

DTF printing is an exciting opportunity for start-ups and small businesses looking to offer high-quality prints on a wide variety of fabrics. By understanding the DTF printing basics and using the right equipment like Adelco’s DTF Printer and DTF Cutter, you can create professional-grade garments that your customers will love.

Start your DTF journey today with Adelco’s full range of start-up printing solutions and discover how you can take your textile printing business to the next level.

Recent articles

Why Precision Matters: The Role of Accurate Cutting in DTF Printing

Eco-Friendly Printing: How Integrated DTF Systems Reduce Waste