Can DTG Grow and Boost your screen Printing Business.

We explore what's involved for a business planning a move from traditional screen-printing to digital DTG.

You have mastered the art of screen printing, your customers are happy and your business is secure. Keeping an eye on costs and print production will allow you to maintain businesses growth and ensure you continue to meet the needs of your customers.

You will be pleased to know that there are no set-up costs with our DTG printers. Our range of printers have low volume runs and faster turnaround, so it’s no surprise that many screen printing businesses have incorporated Direct to Garment printing into their workflow. DTG printing is the obvious addition to your existing printing business and is something that shouldn’t be ignored in 2018.

New HD Technology has reduced the cost per print up to 46% compared to just two years ago which is covered in more detail later in this blog.

What is DTG?

Direct to garment printing has been around for almost 20 years and has evolved considerably over this time with faster print speed, print quality and colour gamut. Although the actual process remains the same, system reliability has changed dramatically in recent years.

The process primarily consists of printing graphics directly onto garments using inkjet technology. This technology uses digital print heads that rapidly fires ink through small nozzles directly onto the fabric, with precision and accuracy.

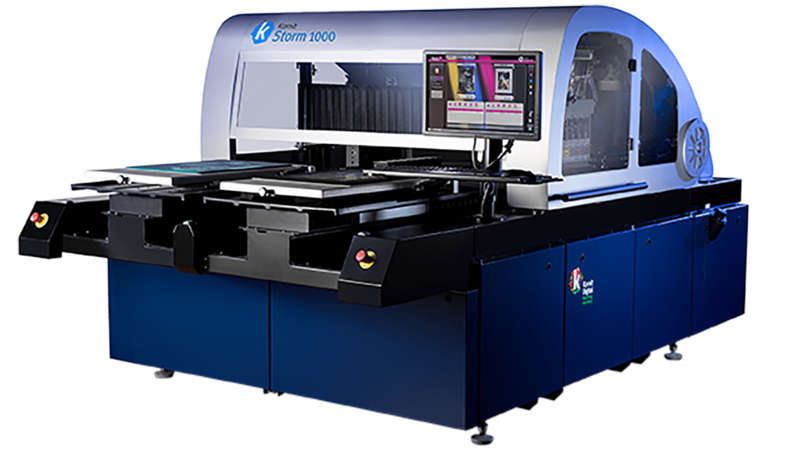

Entry level printers range from approximately 92 nozzles through to the high end Kornit machines that use as many as 24 Spectra heads, each containing 256 nozzles. Although the Kornit machines have more nozzles it allows for the lowest ink utilisation per print (lowest cost per print, also assuring that the image is crisp and precise.

Kornit also uses linear motors, which work on magnetic fields for all the movements within the machine, and are considered to be the most accurate motors in the industry.

When the printing has finished the garment would then be dried either with a heat press or a hot air dryer depending on the system chosen. Please note that on a dark garment a pre-treater is needed prior to printing, this can be done in a special pre-treatment machine, which is sprayed on by hand. The Kornit printer range has this process built into the printing machine to save time and labour during the printing process.

Without any additional set up cost, the print can be changed to any size, shape, design or colour that the customer requires. This allows flexibility with the size of the print run and has taken the e-commerce world by storm allowing each individual customer to have their own designs printed as a one off.

This has also opened the way for artists, graphic designers, schools, clubs etc to print their own designs and to venture into the apparel ecommerce sector. Using larger companies with DTG machinery to print for them. Or to invest in their own DTG machinery.

Direct to garment printing like most processes can be improved with practise, technique or trial and error. With changeables such as pre-treatment and white under base, the finished results can be dramatically improved with staff training.

Both have a place:

With cheap ink costs, ease of use and speeds on modern day automatics – screen printing is perfect for the larger runs, offering a fast turnaround and added special colour finishes.

DTG is bridging the gap and is now a viable option for lower run lengths from screen print. It can also pick up the sampling for runs that are still better justified as Screen Print.

DTG is now comparatively cheaper than that of screen prints for smaller runs.

Technology in the DTG market has advanced a lot in the last few years, and there are direct to garment printers that not only have the CMYK ink pallet but also additional Red & Green colours that improve the digital colour gamut. Due to the printer’s ink recirculation technology and built-in pre-treatment processes, ink costs have been significantly reduced.

The latest technology advances include:

- Additional red and green colours to the standard CMYK to expand the colour gamut

- Re-circulating print heads …..

- Kornit have released a HD series of printer for 2018, which further reduces print cost by:

- reducing the droplet size

- introducing a colorgate RIP software to hit specific pantone colours

- drop size reduction and new ink formulation provides softer hand feel and reduction of your print cost by as much as 46%

Staffing requirements are greatly reduced compared to that of screen printing. A lot of companies have discovered that with little training, your existing technical staff will be able to master the new machinery and print process with ease.

Initial Outlay

If you are already conquering the screen printing market, you will find that you already have some of the machinery you need to cure the DTG ink. Your existing hot air conveyor dryers could be suitable for the DTG water based inks.

Although the initial outlay of the DTG machine can be costly, you could save money on having to purchase a dryer. There are also many grants available throughout the UK that could help cover some of the upfront costs. Have a look at the Business Growth hub in your area for more information.

Companies who don’t take advantage of these grants could be losing out from business growth opportunities. These grants can give you up to 15% of the capital outlay, which would significantly reduce the cost of the machinery. Don’t forget that your new DTG machine is a valuable asset on your balance sheet and with excellent ROI (Return on Investment), they hold their value for years to come.

Hopefully this article allows you to see the potential benefits of direct to garment printing and the costs and finance involved. The next step would be researching the DTG machines that are available. There is a broad range currently on the market and the benefits vary according to your budget. If you are starting out in direct to garment printing then going down the second-hand route might be more viable.

What Direct to Garment printer would suit my needs?

As mentioned there are printers to suit all budgets but (as with all things) you get what you pay for. I have taken the bestselling printers from each price range to give an idea of what is out there.

Go into explanation of how it can integrate with screen prints. If a business owner is going to make an informed decision they need to know how DTG could fit into their current screen printing work flow.

Entry Level

Starting with the Epson Surecolor, this is a great entry level printer at under £10k, small enough to fit in anywhere, with high quality prints. Although this is slow with high print costs.

Mid-Range

In the Mid-price range, the Brother have just launched the GTX. This is but still has high print and pre-treatment costs.

High-End

At the top of the tree you will find the Kornit range, which is the most expensive outlay. Despite the high price tag, you benefit by having the lowest print costs, built-in pre-treatment and faster throughput.

Don’t get left behind!

With many established screen printers expanding into Direct to Garment printing, now isn’t the time to hold back. Screen printers who have diversified into the DTG market are overall experiencing major benefits. The work from smaller run lengths, e-commerce, and supporting events has made the investment pay off.

If you have the order volumes and are wanting to invest or expand your business then Direct to Garment Printing is the obvious choice.

For further details or a demonstration call us now on 01420 488388 or e-mail sales@adelco.co.uk

Recent articles

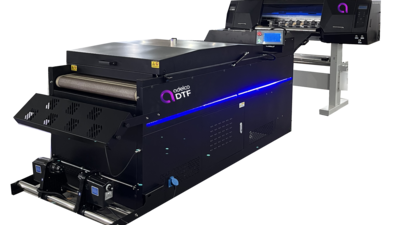

Why Precision Matters: The Role of Accurate Cutting in DTF Printing

Eco-Friendly Printing: How Integrated DTF Systems Reduce Waste