Curing today's textile inks

The importance of curing within the screen-printing process is crucial. This helpful article walks you through all you need to know.

Curing today's textile inks

The importance of curing within the screen-printing process is crucial. A lot of time goes into creating the design, making the screens and printing the garments. To have a bad cure after all this hard work can be damaging to the company.

Curing is the chemical bonding process that happens when the ink is heated to a certain temperature, the pigment bonds to the fabric and the water evaporated. Bad curing is a common problem, but there are number of things to look out for and to put in place to ensure consistent and effective curing:

Getting it right!

Under curing: Things to look out for in an under cured print is the hand feel, is the print still wet/tacky? This implies under curing. Having the print wash out or fade in the wash cycle, this is also known as crocking, to test for this, rub a white piece of cloth against the print and the print should not rub off, if it does the print is not cured properly. Overlapping a garment when put into the dryer will result in the print not receiving a uniformed cure, producing a decaying print.

Over curing: This is not as common as under-curing but can result in the fabric ripping very easily. In order to prevent the above from happening there are steps you can take to ensure constant and effective curing:

Stretch tests: This involves stretching about two thirds of the fabric, if the fabric cracks and does not retract when released, this implies under curing.

Regular heat tests: Using a heat gun (non-contact pyrometer) for checking the temperature of the print as it is coming out of the dryer. Or heat strips that have temperature readings on them will indicate the temperature as the garment is going through the dryer. These testing systems are inexpensive to purchase and give a basic guide to product temperatures in the dryer.

Having inconsistent temperatures within the dryer oven can be a cause of under or over curing and mean that products are given more time in the oven than necessary to compensate for uneven temperatures within the dryer.

We recommend using a Digital Thermo-probe to test your dryer and ensure that temperatures are accurate and compare to those on the dryer settings. This system enables viewing of the dryer temperature as it runs through the dryer and enable checking of temperature consistency from side to side and through the dryer. For more understanding of your dryer temperature, Thermo-probes can be supplied that measure multiple points across the width of the dryer and map the temperature every 2 seconds as the belt passes through. Such a system will provide on-going knowledge and understanding of the dryer temperatures and enable you to keep on top of curing consistency.

Machinery maintenance: Make sure that the dryers are serviced and cleaned regularly to ensure temperature consistency. The old adage “look after your equipment and it will look after you” is key for consistent curing.

Look after your equipment and it will look after you

Waterbased / Discharge ink

These can only be reliably cured through a hot air dryer, as the ink needs to be cured for longer. Time and temperature are crucial to the outcome, getting these factors wrong can result in a disastrous finish.

Rapid removal of water content through high airflow and an efficient exhaust system is key to the best and fastest cure result. This is down to the efficiency of the dryer system used. Only when the water content is removed from an ink film layer, will the layer get up to curing temperature and commence molecular bonding of pigments required to provide wash fastness.

Plastisol inks

These inks require the shortest dry/cure time, and must usually reach a temperature of 160 degrees C, to be fully cured, depending on the Plastisol ink type used. Plastisol inks can feel dry to the touch but still be under cured. They can be cured through an infra-red dryer as well as hot air dryers. The infra-red option is cheaper to buy but hot air dryers are well worth the investment. This process is kinder to the fabric, and has better film layer penetration for a better cure.

Digital printing

Digital textile inks have the same basic curing properties of water-based screen inks and in fact, the importance of the points recommended are often greater to ensure complete cure of the various pre-treatment and ink combinations used. Therefore Digital Textile inks are almost always water based inks, and will cure best through a hot air dryer. A heat press option, is much cheaper, but can leave marks on the fabric around the outside of the print. It is also much more labour intensive and human error is much more prevalent. Using a hot air dryer that you use for screen prints can easily be adapted for your digital prints, by changing the temperature and speed settings.

Getting the right dryer for you.

There are many different types of dryer that are on the market, including hot air dryers, heat presses and infra-red dryers.

One of the most important things to consider when buying a dryer is what size to buy, this would be determined by how many prints you produce an hour and the time required to cure. You will also need to factor in future growth. The best dryers will have additional modules you can purchase at a later date to increase the length and therefore curing throughput. When your business grows, your dryer can grow with you. Due to technological advances there are options available to cure both screen and digital prints on the same dryer at the same time, saving valuable floor space, machine investment and labour costs. Adelco have the Dual conveyor dryer, which is two dryers on top of each other for maximum throughput using less floor space, as well as split belt and double oven dryer options which provide total flexibility in curing all ink systems on to any fabric type.

The curing process is a crucial one and needs thought, investment and most importantly testing to ensure perfect results and a trouble free operation.

Recent articles

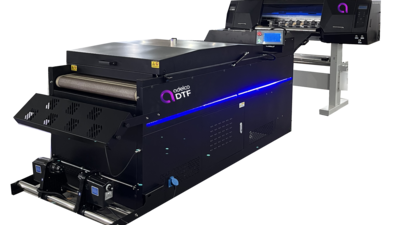

Why Precision Matters: The Role of Accurate Cutting in DTF Printing

Eco-Friendly Printing: How Integrated DTF Systems Reduce Waste