Plastisol V's Water-based ink

With many different kinds of ink available, choosing the right ink type can be a complex and important decision for today’s screen printer.

Plastisol V's Water-based ink

With many different kinds of ink available, choosing the right ink type can be a complex and important decision for today’s screen printer. Mark Smith, managing director of Adelco, explains further.

The main two types of ink used in textile printing are plastisol and water-based ink. By looking at both the positive and negative qualities you can decide which will work best for your print shop.

Water-based inks were first used when the screen printing industry was forming in the early 1900s. These inks were very thin and difficult to work with and it wasn’t until plastisol was introduced in the mid-1900s that the art of screen printing onto fabrics became hugely popular and mass production of this process started.

While plastisol inks have become eco-friendlier over recent years the tide is turning back towards water-based ink due to the softer hand feel, improvements in screen stability and the fact that it remains the most eco-friendly and ethical option.

Let’s take a more in-depth look…

Plastisol Ink

Plastisol is a suspension of PVC or other polymer particles suspended in a plasticising emulsion.

They need to be cured and reach a temperature of about 160°C for full curing, which is an instant gelling process once the full printed layer is up to temperature. The ink tends to sit on the fabric surface, giving an opaque raised plasticised texture. The ink is easy to use as it maintains its consistency and doesn’t dry out.

Curing plastisol ink

Curing of ink types s is an important consideration when choosing which to go for. Plastisol can be cured through infra-red or hot air dryer types provided the full ink layer hits the required temperature.

However, hot air convection dryers will provide a better cure with less affect to fabrics since the heat transfers through heavier ink layers better than with infra-red heat sources and has less effect to heat sensitive fabrics. Consistency of heat in a hot air dryer is essential to achieve the best cure with minimum fabric effect. Hot air dryers with high velocity jet air are more efficient, but generally require more energy, hence the popularity of gas fired models, being much more energy efficient.

| Plastisol inks | |

| Pros | Cons |

|

|

|

|

|

|

|

|

|

Water-Based Inks

Water-based ink is any ink which uses water as a liquid base to carry the pigment. Water molecules are smaller than oil-based molecules, making them move quicker. This combined with the pigment size difference makes them evaporate quicker, which can be problematic. The lower viscosity (thinner) consistency soaks into the fabric, making the handle much softer.

There are a number of different water-based inks to choose from including:

- RFU (ready for use) – These inks come ready mixed and are offered in a large selection of colours.

- HAS (high solid acrylic) – A new kind of water-based ink that has a thicker binder to create a viscosity similar to that of plastisol. HSA inks take longer to dry on the screen and can stretch and stack on top of each other. Making them ideal for more complex printing techniques and they have an excellent hand feel.

- Water-based ink mixing systems – Gives more control over the colours and ink mixtures, giving the choice to create any colour of ink from a standard product base. This allows for a greater control over opacity and print coverage.

There are also various ink additives available to enable curing of the ink at a much lower temperature.

Curing water-based inks

When curing water-based ink, water content is removed from the print best by high velocity air flow and an efficient exhaust system, dispersing the water content through steam.

It is important that air can circulate around the garments and is exhausted well to prevent a build-up of water vapors within the dryer, resulting in an ineffective cure. Temperature control and stability is also crucial to enable the prints to reach the recommended temperature for the correct amount of time to achieve a full cure. High velocity Jet air dryers are therefore highly recommended for consistent curing of all water-based ink systems.

| Water-based inks | |

| Pros | Cons |

|

|

|

|

|

|

|

|

|

So – which is best?

There is certainly a lot to think about. From an environmental and ethical point of view there is a clear winner in water-based, but from a user friendly and financial standpoint, plastisol remains a viable choice.

With innovation and investment being poured into water-based alternatives, they are becoming more user friendly and easier to handle and are often a necessary choice to maintain an ethical standpoint and softer more breathable finished product.

Recent articles

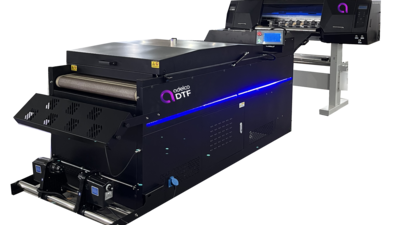

Why Precision Matters: The Role of Accurate Cutting in DTF Printing

Eco-Friendly Printing: How Integrated DTF Systems Reduce Waste