Top 5 Benefits of Combining Printing and Cutting in One DTF System

This article highlights the top five benefits of using an integrated DTF system and how it can transform your production process.

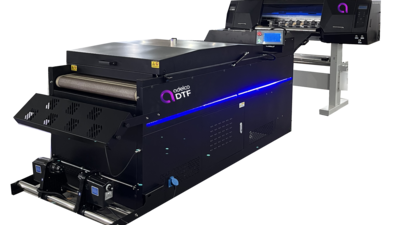

In the fast-paced garment printing world, efficiency and precision are essential for success. Direct-to-film (DTF) technology has revolutionised the industry by offering vibrant, durable prints on various fabrics. Now, with the development of DTF machines that combine printing and cutting in one streamlined system, businesses can enhance their DTF workflow solutions to be even more efficient.

1. Increased Production Speed

The most immediate benefit of DTF machines is the significant boost in production speed. Traditionally, separate machines are used for printing to cutting, requiring manual intervention to transfer designs between each step. This process takes time and increases the risk of errors and misalignment.

By combining both processes into one machine with print-cut integration, you can automate the workflow, allowing seamless transitions between printing and cutting. This faster production process is crucial for businesses handling high-volume orders or tight deadlines, enabling them to meet customer demand without compromising on quality.

Adelco’s DTF Inline Integrated Print & Cut Systems are designed specifically to handle high-volume production with maximum efficiency, making them an ideal choice for businesses looking to enhance their workflow.

2. Improved Precision and Accuracy

When printing and cutting are done separately, there’s always a risk of misalignment, which can lead to wasted materials and inconsistent results. DTF machines ensure that printing and cutting processes are perfectly aligned by automating both tasks in a single step.

This ensures that each cut is accurate and that the design remains flawless, even on complex or detailed prints. Whether you're printing on textiles or exploring new surfaces with UV DTF systems, which allow printing on materials like glass, metal, and plastic, precision is key to maintaining the quality your customers expect.

For high-precision and consistent results, explore Adelco’s UV DTF Systems for expanded printing capabilities on non-fabric surfaces.

3. Cost Efficiency

While investing in a DTF machine may seem like a higher initial cost, the long-term savings make it a highly cost-effective solution. By consolidating printing and cutting into one system, businesses can reduce the number of machines they need, cutting down on maintenance costs and space requirements.

Fewer errors and misaligned prints also mean less material waste, saving money in the long run. Adelco’s DTF Cutter, for example, offers high-precision cutting that reduces material wastage, ensuring that your production process remains cost-effective and efficient.

4. Space-Saving Solution

For businesses with limited workshop space, finding room for multiple pieces of equipment can be challenging. A print-to-cut integration system consolidates all processes into a single production line, freeing up valuable workspace for other essential tools or expanding your production capacity.

This space-saving benefit is ideal for small to medium-sized businesses, allowing them to optimise their production setup without compromising on quality or speed. Adelco’s DTF Printer offers a compact yet powerful solution for any business looking to enhance their workflow in a limited space.

5. Streamlined Workflow

One of the biggest advantages of using an integrated DTF workflow solution is the simplicity it brings to your operations. With fewer machines to manage, operators can focus more on production quality rather than managing multiple devices. The automation provided by DTF machines reduces the risk of human error, ensuring consistency in every print.

The integration of printing and cutting in a single system not only speeds up the production process but also improves overall operational efficiency. With solutions like Adelco’s DTF Inline Integrated Print & Cut Systems, you can streamline your workflow, increase output, and maintain high-quality standards across every product.

Conclusion

Combining printing and cutting into one integrated system offers numerous benefits, from boosting production speed to improving accuracy and reducing costs. By adopting DTF machines, businesses can enjoy a more efficient, cost-effective, and space-saving workflow, all while maintaining the precision and quality that customers demand.

Whether you’re looking for a high-performance DTF Printer, a precision DTF Cutter, or advanced UV DTF systems for printing on a variety of surfaces, Adelco offers a comprehensive range of solutions designed to meet the needs of modern businesses.

Explore Adelco’s full range of DTF workflow solutions to discover how you can streamline your operations and produce high-quality products more efficiently:

• DTF Inline Integrated Print & Cut Systems

Recent articles

Why Precision Matters: The Role of Accurate Cutting in DTF Printing

Eco-Friendly Printing: How Integrated DTF Systems Reduce Waste