The Ultimate Guide to Integrated Print-and-Cut Systems for DTF Printing

In the ever-evolving world of textile printing, Direct-to-Film (DTF) technology is reshaping the industry with its innovative approach to garment decoration.

As DTF printing gains popularity, integrated print-and-cut systems and DTF machines are becoming essential for businesses seeking to enhance production efficiency. This comprehensive guide explores how these systems can optimise your DTF printing process, the equipment available, and how to select the best solution for your business.

What are Integrated Print-and-Cut Systems for DTF Printing?

DTF printing involves transferring designs onto specialized film. Traditionally, this process requires manually weeding and cutting the designs from the film, which adds complexity and time to production. However, integrated print-and-cut systems simplify the process by seamlessly combining both printing and cutting steps into a single, efficient workflow.

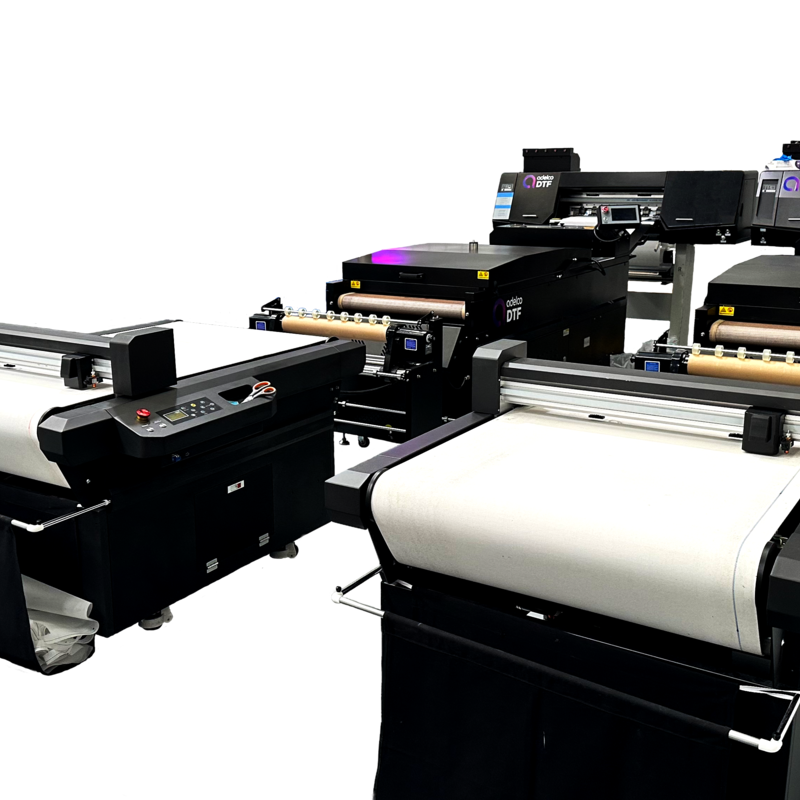

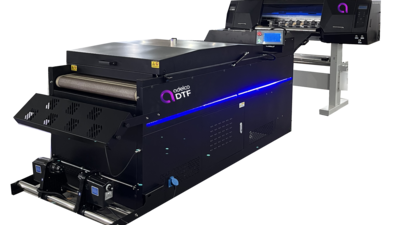

Adelco offers solutions such as the DTF Inline Integrated Print & Cut Systems for businesses prioritising efficiency and high-volume output. These machines are designed to handle large-scale DTF printing projects while maintaining the highest quality standards.

Understanding DTF Machines

DTF Inline Systems are advanced equipment designed to handle multiple processes—such as printing, powder shaking, drying, and cutting—within a single production line, eliminating the need for separate machines. Adelco's DTF systems streamline workflows and significantly reduce production time, enhancing overall efficiency.

Key benefits of DTF Inline Systems include:

• Streamlined Production: With a DTF Inline System, printing to cutting occurs without needing to switch between equipment, resulting in faster turnaround times and increased production capacity.

• Cost Efficiency: DTF Inline System offer an all-in-one solution, reducing the need for multiple machines and cutting maintenance costs.

• Space Optimisation: These systems are ideal for businesses with limited space, combining the printing and cutting processes into a single unit, freeing up valuable workshop space.

• Enhanced Precision: Integrated systems ensure perfect alignment between print to cut, reducing errors and wastage. This precision is key to producing professional-grade results every time.

Adelco’s DTF Cutter and DTF Printer are prime examples of equipment designed to boost production efficiency, providing businesses with tools to optimise their DTF printing processes.

The Range of DTF Systems Available at Adelco

Adelco offers a variety of DTF printing systems tailored to different business needs, from entry-level machines to industrial-scale printers. Each system provides unique benefits suited to specific production environments, ensuring that every business can find the right solution.

• Adelco DTF Printer: This high-performance printer delivers exceptional print quality for vibrant, detailed designs. It is ideal for businesses that need to produce intricate prints on various fabrics. The advanced ink technology ensures designs remain sharp and durable after washing.

• DTF Cutter: Ensuring precise cutting of DTF designs, this machine eliminates the need for manual intervention. It handles a wide range of sizes and shapes, making it a versatile solution for any DTF printing operation.

• DTF Inline Integrated Print & Cut Systems: Designed for businesses aiming to integrate the entire process into one machine, this system offers both printing and cutting functionalities, ideal for high-volume production environments.

• UV DTF Systems: UV DTF technology enables printing on non-fabric surfaces such as glass, metal, and plastic, expanding business opportunities beyond textiles.

Improving DTF Printing Efficiency with Integrated Print-and-Cut Systems

Integrating print-and-cut systems into your DTF workflow enhances production efficiency by streamlining the entire process, from printing to cutting. These systems provide:

• Faster Turnaround Times: By automating the printing and cutting process, you can significantly reduce the time taken to complete orders, critical for high-volume or tight-deadline projects.

• Reduced Errors: Manual processes carry the risk of misalignment during cutting, leading to wastage. Integrated systems ensure perfect alignment between print and cut, reducing material waste and ensuring consistent quality.

• Scalability: As your business grows, integrated systems provide scalable solutions capable of handling larger volumes without compromising on quality or efficiency.

Why Choose Adelco for Your DTF Printing Needs?

Adelco is a trusted name in the digital printing industry, offering innovative and reliable solutions. Their range of DTF systems, including DTF Printers, DTF Cutters, and UV DTF systems, is designed to meet the diverse needs of businesses within the garment and textile industry.

By choosing Adelco, you invest not only in cutting-edge equipment but also in a dedicated team of experts committed to providing ongoing support and guidance. Whether you're upgrading your existing setup or starting fresh, Adelco offers solutions that keep you competitive in a rapidly changing market.

Elevate Your DTF Printing with Integrated Print-and-Cut Systems

By adopting integrated print-and-cut equipment and DTF Systems, you can streamline production, improve accuracy, and increase output. Whether seeking high-performance printers, precision cutters, or versatile systems, Adelco offers a comprehensive range of DTF solutions tailored to your needs.

Explore the possibilities and elevate your DTF printing with Adelco’s cutting-edge solutions:

• DTF Inline Integrated Print & Cut Systems

Investing in the right equipment can revolutionise your business, streamlining your workflow and delivering high-quality products to your customers with ease.

Recent articles

Why Precision Matters: The Role of Accurate Cutting in DTF Printing

Eco-Friendly Printing: How Integrated DTF Systems Reduce Waste